2 月 . 17, 2025 15:27

Back to list

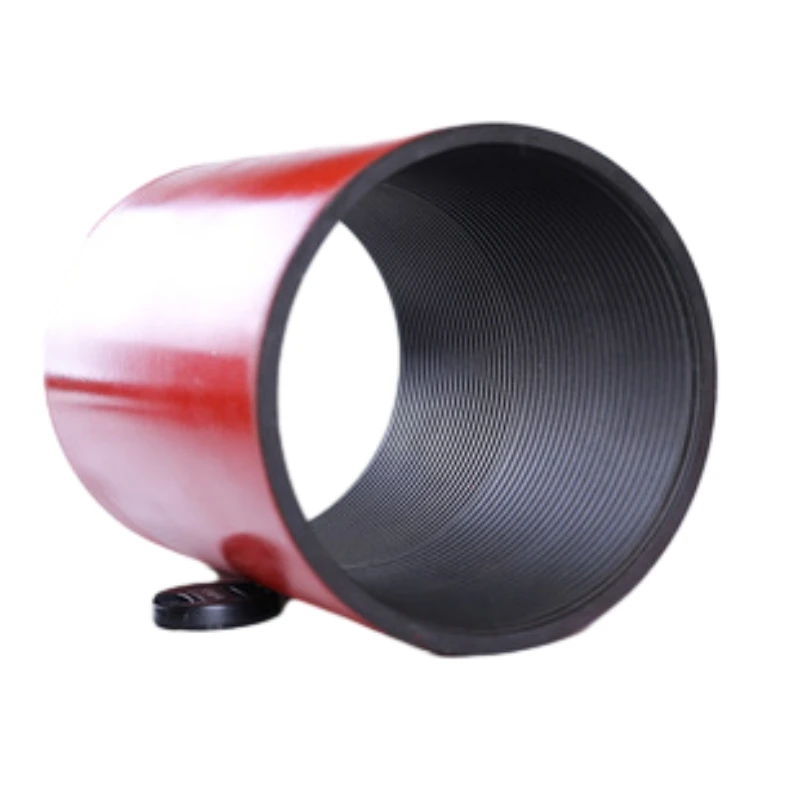

1 1 2 stainless steel coupling

The 1 1/2 stainless steel coupling, an understated yet significant component in the realm of engineering and construction, plays a crucial role in ensuring the seamless operation of complex systems. This robust hardware piece is designed to connect two shafts together at their ends for the purpose of transmitting power. The use of stainless steel in its construction grants it remarkable durability, resistance to corrosion, and an exceptionally long life span, making it an indispensable element in a variety of applications.

The environmental impact of using stainless steel couplings is also a factor worth considering. Stainless steel is highly recyclable, and using these couplings can contribute to sustainable practices within an industry. Once a coupling reaches the end of its life cycle, it can be recycled and repurposed, reducing waste and the demand for new raw materials. As industries move towards greener practices, the adoption of stainless steel components is likely to increase, making them a future-proof choice for businesses aiming to reduce their carbon footprint. For businesses concerned with compliance and safety standards, stainless steel couplings offer a reliable solution. Given their resilience and stability under pressure, they meet stringent industry regulations and minimize the risk of mechanical failure, which can otherwise have significant safety and financial repercussions. The high melting point of stainless steel further adds to its safety profile, as it is less likely to fail under high-temperature conditions. Overall, the decision to implement 1 1/2 stainless steel couplings in a mechanical setup is not just an investment in hardware, but an investment in the operational reliability and efficiency of an entire system. For engineers and procurement specialists, the benefits of reduced maintenance costs, improved performance, and compliance with environmental and safety standards make stainless steel couplings not just a choice, but a necessity. As industries continue to evolve and demand more from their mechanical systems, the role of high-quality materials like stainless steel will only become more pronounced. Businesses looking to future-proof their operations are well advised to consider the myriad benefits that stainless steel couplings offer, ensuring robust, reliable, and efficient solutions for the challenges of tomorrow.

The environmental impact of using stainless steel couplings is also a factor worth considering. Stainless steel is highly recyclable, and using these couplings can contribute to sustainable practices within an industry. Once a coupling reaches the end of its life cycle, it can be recycled and repurposed, reducing waste and the demand for new raw materials. As industries move towards greener practices, the adoption of stainless steel components is likely to increase, making them a future-proof choice for businesses aiming to reduce their carbon footprint. For businesses concerned with compliance and safety standards, stainless steel couplings offer a reliable solution. Given their resilience and stability under pressure, they meet stringent industry regulations and minimize the risk of mechanical failure, which can otherwise have significant safety and financial repercussions. The high melting point of stainless steel further adds to its safety profile, as it is less likely to fail under high-temperature conditions. Overall, the decision to implement 1 1/2 stainless steel couplings in a mechanical setup is not just an investment in hardware, but an investment in the operational reliability and efficiency of an entire system. For engineers and procurement specialists, the benefits of reduced maintenance costs, improved performance, and compliance with environmental and safety standards make stainless steel couplings not just a choice, but a necessity. As industries continue to evolve and demand more from their mechanical systems, the role of high-quality materials like stainless steel will only become more pronounced. Businesses looking to future-proof their operations are well advised to consider the myriad benefits that stainless steel couplings offer, ensuring robust, reliable, and efficient solutions for the challenges of tomorrow.

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products