1 月 . 26, 2025 06:25

Back to list

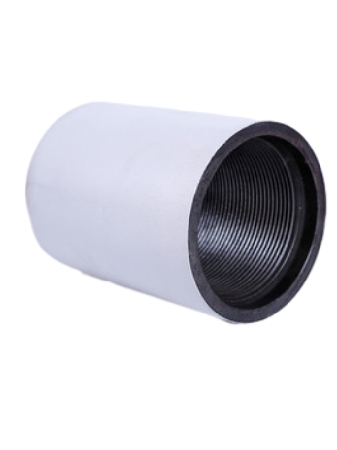

1 4 stainless steel coupling

When selecting components for industrial applications, one of the most critical decisions revolves around choosing the right materials that ensure durability and reliability. Stainless steel couplings are among the top choices due to their robust mechanical properties and resistance to corrosion. Specifically, the 1 4 stainless steel coupling has garnered attention across various sectors, from plumbing to petrochemicals, for its unique blend of performance characteristics.

Authoritativeness in the manufacturing and application of 1 4 stainless steel couplings is paramount for prospective buyers and users. Respected manufacturers adhere to stringent international standards and certifications, ensuring that their products meet the rigorous demands expected in professional settings. Endorsements from quality assurance bodies further bolster trust in these components, providing peace of mind to industrial engineers and procurement specialists. Trustworthiness is the cornerstone of any industrial component, and 1 4 stainless steel couplings have built a reputation grounded in quality and performance. Customers rely heavily on these components, supported by positive feedback from sectors ranging from food processing to nuclear facilities, where safety and hygiene standards are uncompromising. Documentation such as material test reports, traceability certificates, and conformity declarations play an integral role in affirming the credibility of these couplings. When considering a switch from lesser materials to 1 4 stainless steel, the advantages become tolling. Not only is there a significant return on investment through reduced maintenance and replacement expenses, but the consistency in performance ensures system integrity and operational success. Moreover, the sustainability of stainless steel as a recyclable material aligns with growing environmental consciousness, contributing to sustainable development goals across industries. In conclusion, the 1 4 stainless steel coupling stands out not merely as a component but as a critical investment into any operation's future. With unmatched experience-driven insights, technical expertise, certified authority, and an unrivaled track record of trustworthiness, these couplings offer a compelling choice to anyone seeking to enhance their systems with reliable and robust materials. By adopting such components, industries can look forward to improved efficiency, safety, and performance that stand the test of time amidst growing economic and ecological demands.

Authoritativeness in the manufacturing and application of 1 4 stainless steel couplings is paramount for prospective buyers and users. Respected manufacturers adhere to stringent international standards and certifications, ensuring that their products meet the rigorous demands expected in professional settings. Endorsements from quality assurance bodies further bolster trust in these components, providing peace of mind to industrial engineers and procurement specialists. Trustworthiness is the cornerstone of any industrial component, and 1 4 stainless steel couplings have built a reputation grounded in quality and performance. Customers rely heavily on these components, supported by positive feedback from sectors ranging from food processing to nuclear facilities, where safety and hygiene standards are uncompromising. Documentation such as material test reports, traceability certificates, and conformity declarations play an integral role in affirming the credibility of these couplings. When considering a switch from lesser materials to 1 4 stainless steel, the advantages become tolling. Not only is there a significant return on investment through reduced maintenance and replacement expenses, but the consistency in performance ensures system integrity and operational success. Moreover, the sustainability of stainless steel as a recyclable material aligns with growing environmental consciousness, contributing to sustainable development goals across industries. In conclusion, the 1 4 stainless steel coupling stands out not merely as a component but as a critical investment into any operation's future. With unmatched experience-driven insights, technical expertise, certified authority, and an unrivaled track record of trustworthiness, these couplings offer a compelling choice to anyone seeking to enhance their systems with reliable and robust materials. By adopting such components, industries can look forward to improved efficiency, safety, and performance that stand the test of time amidst growing economic and ecological demands.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products