3 月 . 03, 2025 12:38

Back to list

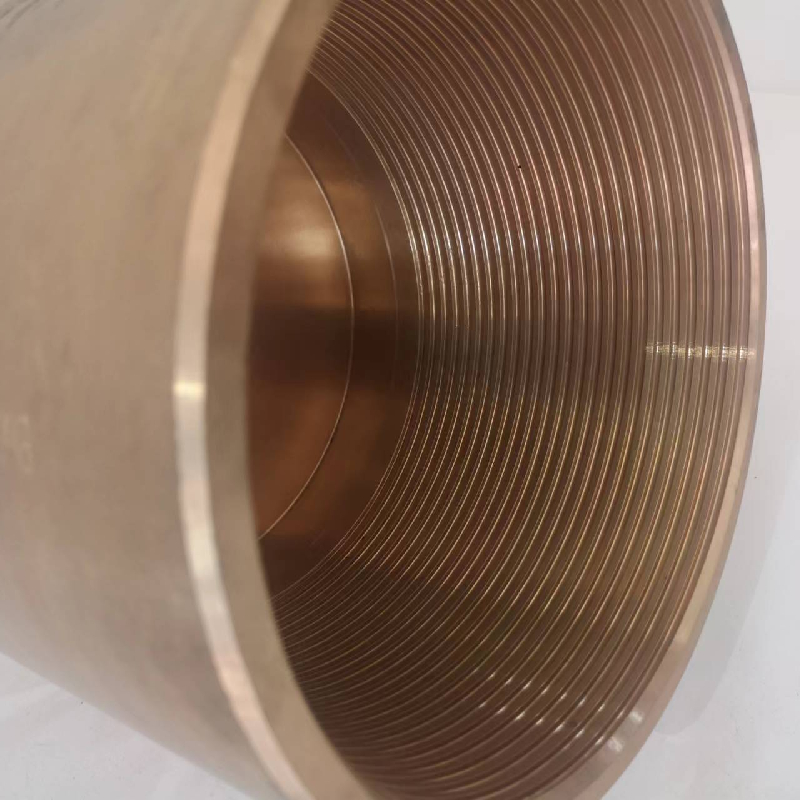

1 4 stainless steel coupling

In the world of industrial piping systems, selecting the right coupling is crucial for ensuring durability and efficiency. 1 4 stainless steel coupling stands out as a superior choice, renowned for its resilience and reliability, particularly in challenging environments. This article delves into the essential nature of these components, offering insights drawn from extensive expertise in the field, along with real-world applications that highlight their effectiveness.

User experience is further enriched by the ease of installation and maintenance associated with these couplings. Installation does not demand specialized tools, thus enabling quicker setup times and simpler adjustments. This is a pivotal advantage in settings where minimizing downtime is critical. The robust nature of stainless steel also ensures that the couplings’ performance remains consistent over time, even under substantial stress, contributing to a more seamless operational workflow. In addition, the alloy's inherent thermal resistance allows the couplings to function effectively across a broad temperature range. This versatility underpins their wide adoption in geographical areas experiencing extreme temperatures, whether hot or cold, thereby emphasizing the adaptability of these couplings to varying environmental conditions. Investing in high-quality 1 4 stainless steel coupling is thus not merely a choice of material but a strategic decision that impacts the entire operational lifecycle of equipment. The benefits it brings, in terms of durability, efficiency, and reliability, align perfectly with the demands of modern industries seeking sustainable and cost-effective solutions. In summary, 1 4 stainless steel coupling’s role in various industrial applications is indispensable. Its proven effectiveness, coupled with an impeccable safety record and compliance with rigorous international standards, makes it an authoritative component in any high-stakes operation. This coupling type epitomizes the pinnacle of engineering excellence, offering value that resonates through tangible operational improvements and superior lifecycle management. Such qualities make it an unmatched choice for industry leaders who prioritize both performance and reliability.

User experience is further enriched by the ease of installation and maintenance associated with these couplings. Installation does not demand specialized tools, thus enabling quicker setup times and simpler adjustments. This is a pivotal advantage in settings where minimizing downtime is critical. The robust nature of stainless steel also ensures that the couplings’ performance remains consistent over time, even under substantial stress, contributing to a more seamless operational workflow. In addition, the alloy's inherent thermal resistance allows the couplings to function effectively across a broad temperature range. This versatility underpins their wide adoption in geographical areas experiencing extreme temperatures, whether hot or cold, thereby emphasizing the adaptability of these couplings to varying environmental conditions. Investing in high-quality 1 4 stainless steel coupling is thus not merely a choice of material but a strategic decision that impacts the entire operational lifecycle of equipment. The benefits it brings, in terms of durability, efficiency, and reliability, align perfectly with the demands of modern industries seeking sustainable and cost-effective solutions. In summary, 1 4 stainless steel coupling’s role in various industrial applications is indispensable. Its proven effectiveness, coupled with an impeccable safety record and compliance with rigorous international standards, makes it an authoritative component in any high-stakes operation. This coupling type epitomizes the pinnacle of engineering excellence, offering value that resonates through tangible operational improvements and superior lifecycle management. Such qualities make it an unmatched choice for industry leaders who prioritize both performance and reliability.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products