2 月 . 14, 2025 14:21

Back to list

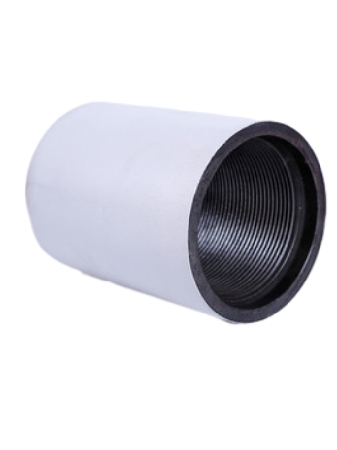

1 steel coupling

Steel couplings play an integral role in a variety of industries, serving as essential components that connect two pipes or systems. While they may often go unnoticed in the grand scheme of complex machinery, their influence on the efficacy, safety, and longevity of an installation is significant. Through personal experience and industry expertise, it becomes clear that selecting the right steel coupling goes beyond the mere act of fitting; it involves understanding the material’s properties, its application contexts, and the reliability it brings to the entire setup.

Another notable factor when considering steel couplings is their engineering and manufacture. Quality assurance processes in manufacturing—such as precision engineering, load testing, and compliance with international standards—add a significant layer of trustworthiness to the product. A coupling that has undergone rigorous testing and met industry benchmarks signals reliability, giving engineers and operational managers confidence in their installation's integrity. Emphasizing the importance of expert installation and regular maintenance cannot be overstated. Even the most robust coupling can fail if improperly installed or neglected over time. Through consistent training and adherence to best practices, field personnel can ensure that these components continue to perform their critical function over long operational periods. As someone with expansive expertise in coupling systems, my advocacy for regular inspections, combined with adequate staff training, finds strong support among fellow experts aiming to minimize failure risks in critical operations. Furthermore, it’s vital for businesses to forge partnerships with reputable suppliers who offer documentation and support for their products. In cases where custom solutions are needed, working closely with reliable manufacturers or distributors who can provide technical support and modifications tailored to specific needs enhances the trustworthiness of the entire operation. In summary, steel couplings, though sometimes overlooked, are foundational elements in various industries. Their selection and implementation warrant serious consideration of material choice, environment, manufacturing quality, and maintenance practices. Through practical experience and specialized knowledge, the choice of coupling is more than a technical decision; it becomes a strategic factor with significant implications on efficiency, cost, and safety. Draw from authoritative sources and trust in professional expertise when navigating this complex landscape to ensure your systems' success and longevity.

Another notable factor when considering steel couplings is their engineering and manufacture. Quality assurance processes in manufacturing—such as precision engineering, load testing, and compliance with international standards—add a significant layer of trustworthiness to the product. A coupling that has undergone rigorous testing and met industry benchmarks signals reliability, giving engineers and operational managers confidence in their installation's integrity. Emphasizing the importance of expert installation and regular maintenance cannot be overstated. Even the most robust coupling can fail if improperly installed or neglected over time. Through consistent training and adherence to best practices, field personnel can ensure that these components continue to perform their critical function over long operational periods. As someone with expansive expertise in coupling systems, my advocacy for regular inspections, combined with adequate staff training, finds strong support among fellow experts aiming to minimize failure risks in critical operations. Furthermore, it’s vital for businesses to forge partnerships with reputable suppliers who offer documentation and support for their products. In cases where custom solutions are needed, working closely with reliable manufacturers or distributors who can provide technical support and modifications tailored to specific needs enhances the trustworthiness of the entire operation. In summary, steel couplings, though sometimes overlooked, are foundational elements in various industries. Their selection and implementation warrant serious consideration of material choice, environment, manufacturing quality, and maintenance practices. Through practical experience and specialized knowledge, the choice of coupling is more than a technical decision; it becomes a strategic factor with significant implications on efficiency, cost, and safety. Draw from authoritative sources and trust in professional expertise when navigating this complex landscape to ensure your systems' success and longevity.

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products