2 月 . 11, 2025 07:27

Back to list

3 8 stainless steel coupling

The importance of material selection in the mechanical coupling industry cannot be overstated. When it comes to enduring strength and reliability, 3 8 stainless steel couplings stand as a superior choice for many industrial applications.

Experience in utilizing 3 8 stainless steel couplings reveals their versatility not only in industrial sectors but also in architectural designs. The aesthetic appeal of stainless steel provides a sleek, modern look that does not sacrifice functionality. In environments ranging from water treatment facilities to high-tech laboratories, the ability of these couplings to withstand aggressive cleaning agents without deteriorating is invaluable. Professional expertise highlights the meticulous manufacturing process of these couplings, which involves precision engineering techniques that meet rigorous industry standards and certifications. This painstaking process ensures the reliability and safety of connection points, a non-negotiable aspect in safety-critical industries. When considering the authoritativeness and trustworthiness of a product like the 3 8 stainless steel coupling, industry professionals rely on certifications from distinguished bodies like the American Petroleum Institute (API) and the American Society for Testing and Materials (ASTM). Such certifications affirm the quality, performance, and safety characteristics essential to trusted manufacturing practices. Moreover, ensuring trust lies in the transparent supply chain management practices by reputable manufacturers who provide detailed insights into the sourcing of raw materials and adherence to environmental and ethical standards. This transparency offers reassurance to engineers and procurement managers who must certify that their choices will not only perform as expected but also align with sustainability commitments. In summary, 3 8 stainless steel couplings possess distinctive properties that make them indispensable across a variety of applications. Their composition ensures durability, resistance to corrosion, and superior mechanical strength, elevating them as a benchmark in the coupling industry. Professionals continue to endorse these couplings not only for their resilience in adverse environments but also for their compliance with global standards of quality and safety. Explorations and testimonials from industrial users reinforce these claims, making 3 8 stainless steel couplings a robust choice for today's demanding engineering challenges.

Experience in utilizing 3 8 stainless steel couplings reveals their versatility not only in industrial sectors but also in architectural designs. The aesthetic appeal of stainless steel provides a sleek, modern look that does not sacrifice functionality. In environments ranging from water treatment facilities to high-tech laboratories, the ability of these couplings to withstand aggressive cleaning agents without deteriorating is invaluable. Professional expertise highlights the meticulous manufacturing process of these couplings, which involves precision engineering techniques that meet rigorous industry standards and certifications. This painstaking process ensures the reliability and safety of connection points, a non-negotiable aspect in safety-critical industries. When considering the authoritativeness and trustworthiness of a product like the 3 8 stainless steel coupling, industry professionals rely on certifications from distinguished bodies like the American Petroleum Institute (API) and the American Society for Testing and Materials (ASTM). Such certifications affirm the quality, performance, and safety characteristics essential to trusted manufacturing practices. Moreover, ensuring trust lies in the transparent supply chain management practices by reputable manufacturers who provide detailed insights into the sourcing of raw materials and adherence to environmental and ethical standards. This transparency offers reassurance to engineers and procurement managers who must certify that their choices will not only perform as expected but also align with sustainability commitments. In summary, 3 8 stainless steel couplings possess distinctive properties that make them indispensable across a variety of applications. Their composition ensures durability, resistance to corrosion, and superior mechanical strength, elevating them as a benchmark in the coupling industry. Professionals continue to endorse these couplings not only for their resilience in adverse environments but also for their compliance with global standards of quality and safety. Explorations and testimonials from industrial users reinforce these claims, making 3 8 stainless steel couplings a robust choice for today's demanding engineering challenges.

Next:

Latest news

-

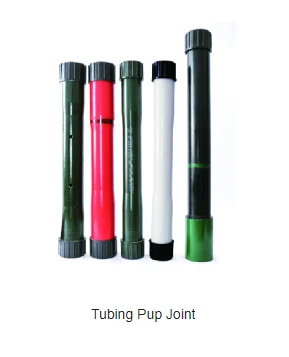

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products