2 月 . 20, 2025 08:22

Back to list

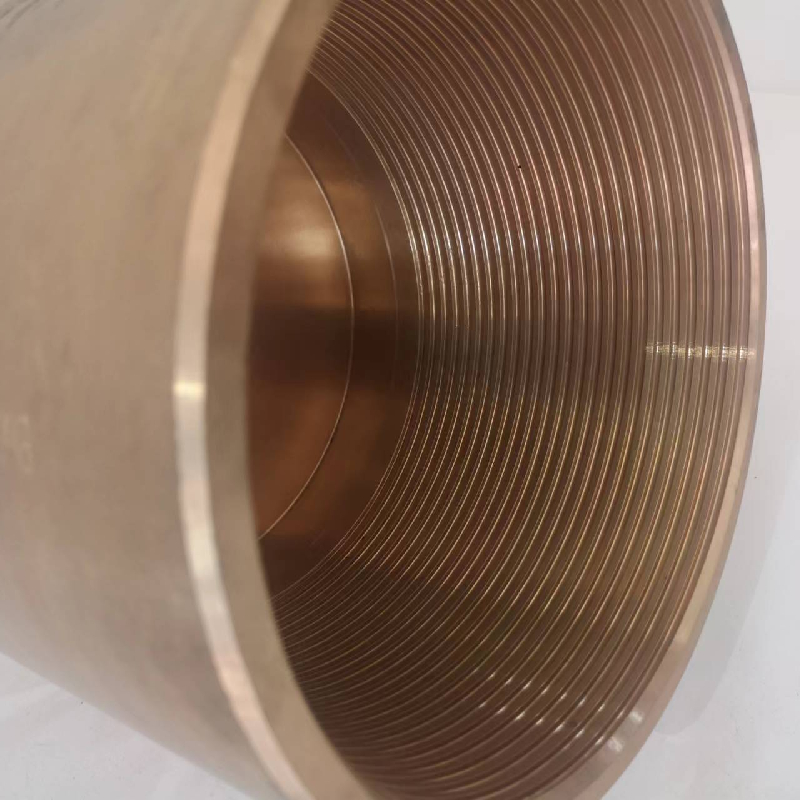

4 stainless steel coupling

Nestled within the vast realm of industrial components, stainless steel couplings stand out as vital connectors that offer unmatched durability and resistance to corrosion. A stanchion for numerous applications, specifically the elusive 4 stainless steel coupling, emerges as a significant player for a myriad of industries, thanks to its robust construction and versatility. Through detailed expertise and practical insights, this article unravels the paramount features and advantages brought forth by this indispensable product.

Marine industries present a challenging test for metal components due to the persistent presence of saline water. Here, stainless steel couplings, renown for their sea-resistant properties, are employed extensively. Not only do they prevent catastrophic failures caused by rust and corrosion, but their robust capacity to withstand high pressure also warrants their utility in critical shipboard systems. Choosing stainless steel couplings translates directly into prolonged service life and fewer replacements, averting costly downtime. From a sustainability perspective, stainless steel couplings are exemplary. They are 100% recyclable, thereby minimizing environmental impact and supporting shifting industry norms towards recycling and sustainability. Their enduring performance reduces resource consumption over time, affirming an organization's commitment to sustainable practices. The most discerning buyers place a premium on not just product quality but also on supplier reputability. A trustworthy supplier offers not only the benefit of premium quality stainless steel couplings but also comprehensive support, from detailed installation guides to post-purchase assistance. Emphasizing certifications and adherence to international standards serves as additional proof of quality and reliability. In conclusion, the 4 stainless steel coupling embodies a multitude of benefits transcending basic connection roles. Its superior material properties, versatile applications across varied industries, and environmental benefits underline its pivotal role in contemporary industrial solutions. For seamless operations, consistent performance, and adherence to quality standards, these couplings remain unrivaled champions in the connectivity arena.

Marine industries present a challenging test for metal components due to the persistent presence of saline water. Here, stainless steel couplings, renown for their sea-resistant properties, are employed extensively. Not only do they prevent catastrophic failures caused by rust and corrosion, but their robust capacity to withstand high pressure also warrants their utility in critical shipboard systems. Choosing stainless steel couplings translates directly into prolonged service life and fewer replacements, averting costly downtime. From a sustainability perspective, stainless steel couplings are exemplary. They are 100% recyclable, thereby minimizing environmental impact and supporting shifting industry norms towards recycling and sustainability. Their enduring performance reduces resource consumption over time, affirming an organization's commitment to sustainable practices. The most discerning buyers place a premium on not just product quality but also on supplier reputability. A trustworthy supplier offers not only the benefit of premium quality stainless steel couplings but also comprehensive support, from detailed installation guides to post-purchase assistance. Emphasizing certifications and adherence to international standards serves as additional proof of quality and reliability. In conclusion, the 4 stainless steel coupling embodies a multitude of benefits transcending basic connection roles. Its superior material properties, versatile applications across varied industries, and environmental benefits underline its pivotal role in contemporary industrial solutions. For seamless operations, consistent performance, and adherence to quality standards, these couplings remain unrivaled champions in the connectivity arena.

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products