1 月 . 26, 2025 00:26

Back to list

Tubing Pup Joint

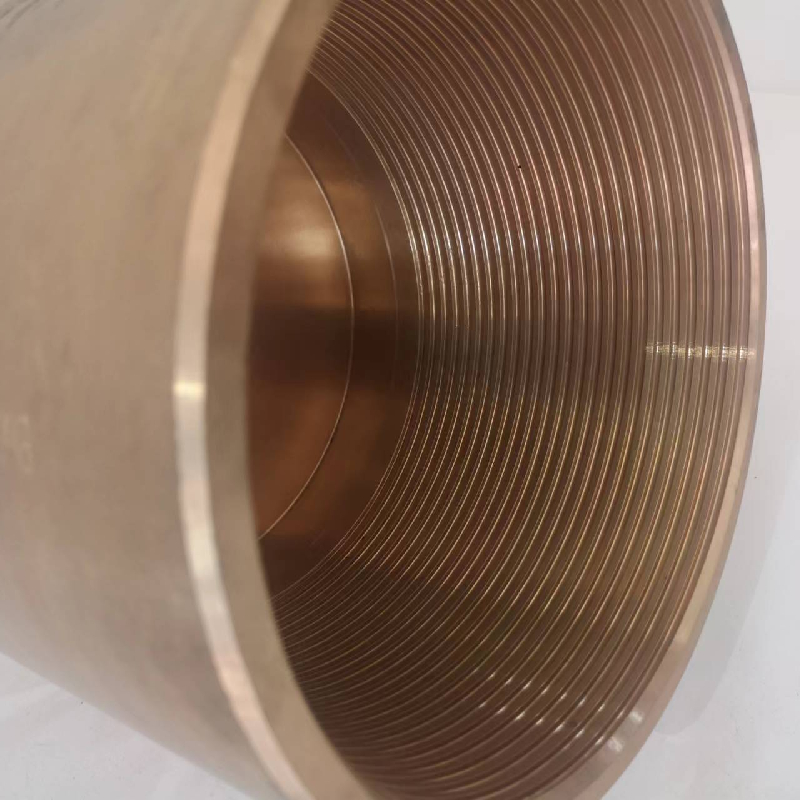

The oil and gas industry relies heavily on precision and durability, particularly when it comes to equipment such as API 5CT couplings. These components are essential for the integrity of casing and tubing systems, ensuring a safe and efficient operation in subsurface conditions that challenge even the most robust materials.

Manufacturers who demonstrate authority in producing API 5CT couplings have established a reputation for quality and innovation. These companies often invest heavily in research and development, ushering in advanced manufacturing techniques and leveraging cutting-edge technology to refine their product offerings continually. This expertise builds a foundation of trust with consumers who rely on these components for critical infrastructure. Trustworthiness is further illustrated by adherence to API guidelines, including regular audits and compliance certificates. Transparency in sourcing materials and ethical manufacturing practices fosters a sense of security among purchasers and operators in the industry. In summary, API 5CT couplings are not just components; they are the backbone of well integrity in oil and gas exploration. Their design and manufacture encompass a blend of real-world application insight, technical prowess, authoritative production standards, and steadfast reliability. As the industry evolves, the continuous improvement of these couplings ensures they meet the ever-increasing demands of global energy production while reinforcing the foundation of trust upon which the API standard stands.

Manufacturers who demonstrate authority in producing API 5CT couplings have established a reputation for quality and innovation. These companies often invest heavily in research and development, ushering in advanced manufacturing techniques and leveraging cutting-edge technology to refine their product offerings continually. This expertise builds a foundation of trust with consumers who rely on these components for critical infrastructure. Trustworthiness is further illustrated by adherence to API guidelines, including regular audits and compliance certificates. Transparency in sourcing materials and ethical manufacturing practices fosters a sense of security among purchasers and operators in the industry. In summary, API 5CT couplings are not just components; they are the backbone of well integrity in oil and gas exploration. Their design and manufacture encompass a blend of real-world application insight, technical prowess, authoritative production standards, and steadfast reliability. As the industry evolves, the continuous improvement of these couplings ensures they meet the ever-increasing demands of global energy production while reinforcing the foundation of trust upon which the API standard stands.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products