2 月 . 03, 2025 05:49

Back to list

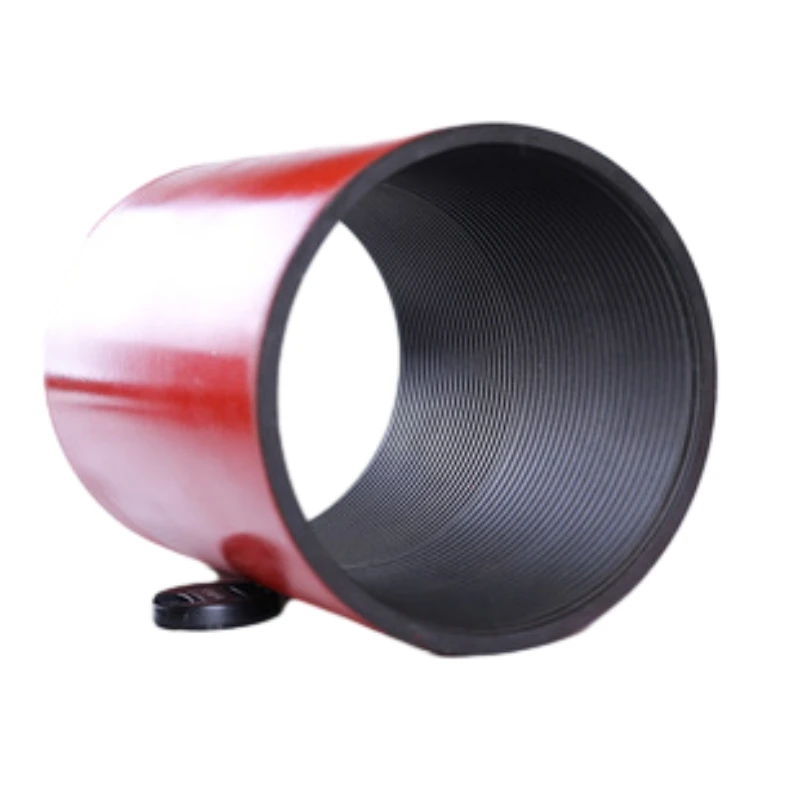

Casing Pup Joint

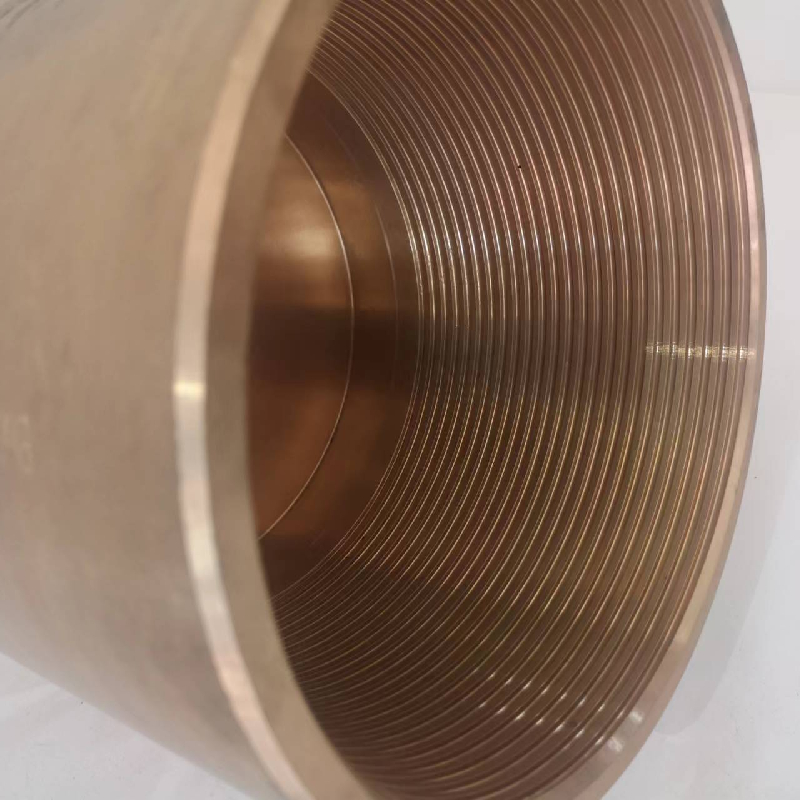

Brass pipe couplings have emerged as a crucial component in plumbing and industrial applications due to their durability and reliability. A blend of zinc and copper, brass boasts not only corrosion resistance but also a lower friction coefficient, making it an excellent choice for fittings that need to withstand the test of time and pressure.

Brass’s reputation as a reliable material is grounded in its authoritativeness—backed by in-depth studies and usage cases. Many industry professionals regard brass fittings as the gold standard, underscoring their efficacy in both simple and complex systems. The metal's ability to self-heal minor scratches through a natural patina process conveys an added layer of protection. Authorities in the plumbing sector often recommend brass for both new installations and retrofits because its physical properties outperform those of many alternative materials. Detailed research papers and case studies further authenticate the superiority of brass couplings, affirming their position as a trusted choice in the plumbing world. Trustworthiness is the cornerstone of any recommendation regarding material choice, and brass pipe couplings consistently deliver on this front. Users find assurance in the fact that these components not only meet but frequently exceed regulatory standards set by plumbing codes and associations. The metal's inherent reliability reduces the frequency of replacements, thus fostering consumer trust. Moreover, manufacturers of brass fittings often provide substantial warranties, reflecting their confidence in the product’s lifespan and performance. Labs standardize and rigorously test these couplings to ensure they adhere to stringent safety and quality benchmarks, reinforcing their credibility. In conclusion, brass pipe couplings stand out in the marketplace due to their dependable nature and versatile applications. Whether your project involves renovating a home’s plumbing system or outfitting a commercial building, considering brass fittings is a wise decision. Their combination of durability, cost-efficiency, and adaptability to various plumbing scenarios makes them a superior choice for those seeking long-lasting and trustworthy solutions. By tapping into the wealth of expertise and authoritative support available, individuals and businesses can make informed decisions that capitalize on the proven benefits of brass pipe couplings.

Brass’s reputation as a reliable material is grounded in its authoritativeness—backed by in-depth studies and usage cases. Many industry professionals regard brass fittings as the gold standard, underscoring their efficacy in both simple and complex systems. The metal's ability to self-heal minor scratches through a natural patina process conveys an added layer of protection. Authorities in the plumbing sector often recommend brass for both new installations and retrofits because its physical properties outperform those of many alternative materials. Detailed research papers and case studies further authenticate the superiority of brass couplings, affirming their position as a trusted choice in the plumbing world. Trustworthiness is the cornerstone of any recommendation regarding material choice, and brass pipe couplings consistently deliver on this front. Users find assurance in the fact that these components not only meet but frequently exceed regulatory standards set by plumbing codes and associations. The metal's inherent reliability reduces the frequency of replacements, thus fostering consumer trust. Moreover, manufacturers of brass fittings often provide substantial warranties, reflecting their confidence in the product’s lifespan and performance. Labs standardize and rigorously test these couplings to ensure they adhere to stringent safety and quality benchmarks, reinforcing their credibility. In conclusion, brass pipe couplings stand out in the marketplace due to their dependable nature and versatile applications. Whether your project involves renovating a home’s plumbing system or outfitting a commercial building, considering brass fittings is a wise decision. Their combination of durability, cost-efficiency, and adaptability to various plumbing scenarios makes them a superior choice for those seeking long-lasting and trustworthy solutions. By tapping into the wealth of expertise and authoritative support available, individuals and businesses can make informed decisions that capitalize on the proven benefits of brass pipe couplings.

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products