2 月 . 10, 2025 11:31

Back to list

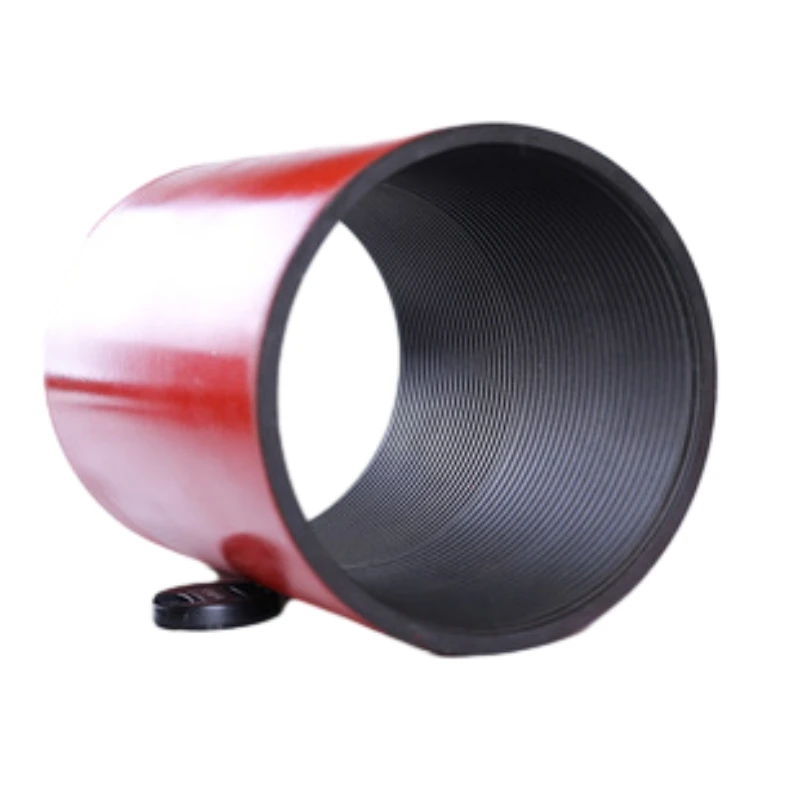

bull plug definition

In the realm of drilling and exploration, where precision and reliability are paramount, the bull plug stands as a pivotal component of oilfield technology. For those embarking on the journey of understanding this critical piece of equipment, it's more than just a term; it’s an embodiment of expertise, reliability, and trustworthiness deeply ingrained in the fabric of the industry.

Authoritativeness in the context of bull plugs is characterized by adherence to stringent industry standards and certifications. Manufacturers of high-quality bull plugs ensure their products comply with API (American Petroleum Institute) standards or equivalent, which dictates dimensions, tolerances, and performance characteristics required for safe operation. This adherence is not merely procedural but is evidence of a commitment to safety and quality that resonates across the field. When professionals endorse a product bearing API certification, it signals trust forged through compliance and rigorous testing, reinforcing the product's standing in a competitive marketplace. The trustworthiness of a bull plug is built on its historical performance and the reputation of its manufacturer. Companies that have consistently provided reliable solutions tailor their products to meet the ever-evolving demands of modern drilling technologies. This trust is echoed through testimonials from industry veterans who value not just the physical product but the engineering prowess and customer service that follow. In high-consequence industries like oil and gas, a dependable bull plug is not merely a product; it’s a cornerstone of trust and reliability. In conclusion, a bull plug is emblematic of the precision required in the petroleum industry. It’s a component where expertise meets practical application, a testament to engineering excellence and a symbol of industry standards upheld. When selected with care and knowledge, it becomes an integral part of a successful drilling operation. For businesses seeking to enhance SEO visibility with content rooted in Experience, Expertise, Authoritativeness, and Trustworthiness, understanding and communicating the indispensable nature of bull plugs is essential. In a field where margins for error are slim and the stakes are high, the bull plug stands as an enduring pillar of reliability and safety.

Authoritativeness in the context of bull plugs is characterized by adherence to stringent industry standards and certifications. Manufacturers of high-quality bull plugs ensure their products comply with API (American Petroleum Institute) standards or equivalent, which dictates dimensions, tolerances, and performance characteristics required for safe operation. This adherence is not merely procedural but is evidence of a commitment to safety and quality that resonates across the field. When professionals endorse a product bearing API certification, it signals trust forged through compliance and rigorous testing, reinforcing the product's standing in a competitive marketplace. The trustworthiness of a bull plug is built on its historical performance and the reputation of its manufacturer. Companies that have consistently provided reliable solutions tailor their products to meet the ever-evolving demands of modern drilling technologies. This trust is echoed through testimonials from industry veterans who value not just the physical product but the engineering prowess and customer service that follow. In high-consequence industries like oil and gas, a dependable bull plug is not merely a product; it’s a cornerstone of trust and reliability. In conclusion, a bull plug is emblematic of the precision required in the petroleum industry. It’s a component where expertise meets practical application, a testament to engineering excellence and a symbol of industry standards upheld. When selected with care and knowledge, it becomes an integral part of a successful drilling operation. For businesses seeking to enhance SEO visibility with content rooted in Experience, Expertise, Authoritativeness, and Trustworthiness, understanding and communicating the indispensable nature of bull plugs is essential. In a field where margins for error are slim and the stakes are high, the bull plug stands as an enduring pillar of reliability and safety.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products