2 月 . 19, 2025 01:28

Back to list

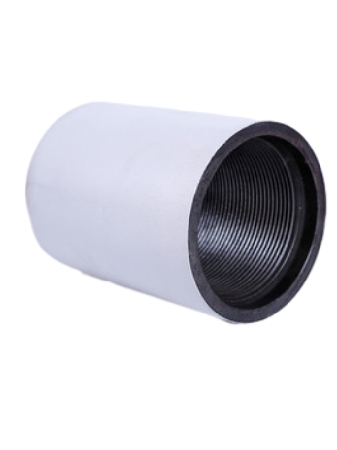

bull plug pressure rating

The concept of bull plug pressure rating may not be widely recognized outside of specific industrial sectors, but for professionals dealing in piping systems, it is a critical component that cannot be overlooked. By understanding what bull plug pressure rating entails, you can ensure that your piping systems operate safely and efficiently, preventing any potential system failures.

Authoritativeness in this domain is maintained by adhering to these established standards and engaging with suppliers and manufacturers that are certified and recognized by regulatory agencies. It’s essential to source products only from reputable companies that have a proven track record for quality and reliability. Their adherence to international standards should be well-documented, which is crucial for maintaining system integrity and safety. Trustworthiness can be reinforced through transparent communication with suppliers and manufacturers. It is crucial to work with partners who can provide certifications and detailed product specifications. This transparency helps to avoid discrepancies in the manufacturing process, ensuring that the specified pressure ratings are met and maintained throughout the product lifecycle. Regular audits and independent testing of the bull plugs can provide additional assurance of their capability to withstand specified pressures. Furthermore, the potential impact of incorrect pressure ratings cannot be overstated, as it can lead to critical failures resulting in environmental hazards, expensive downtime, and increased maintenance costs. Therefore, it's imperative for businesses in sectors reliant on high-pressure systems to invest in thorough training for their engineers and maintenance staff, promoting a culture of safety and precision. In conclusion, bull plug pressure rating is an essential component in ensuring the safety and efficacy of pipeline systems, particularly in high-pressure applications. By leveraging experience, adhering to established industrial standards, and partnering with credible suppliers, companies can maximize the performance and safety of their systems. Maintaining a focus on these fundamental aspects ensures that pipeline systems operate with the utmost integrity, protecting both personnel and the environment from potential hazards.

Authoritativeness in this domain is maintained by adhering to these established standards and engaging with suppliers and manufacturers that are certified and recognized by regulatory agencies. It’s essential to source products only from reputable companies that have a proven track record for quality and reliability. Their adherence to international standards should be well-documented, which is crucial for maintaining system integrity and safety. Trustworthiness can be reinforced through transparent communication with suppliers and manufacturers. It is crucial to work with partners who can provide certifications and detailed product specifications. This transparency helps to avoid discrepancies in the manufacturing process, ensuring that the specified pressure ratings are met and maintained throughout the product lifecycle. Regular audits and independent testing of the bull plugs can provide additional assurance of their capability to withstand specified pressures. Furthermore, the potential impact of incorrect pressure ratings cannot be overstated, as it can lead to critical failures resulting in environmental hazards, expensive downtime, and increased maintenance costs. Therefore, it's imperative for businesses in sectors reliant on high-pressure systems to invest in thorough training for their engineers and maintenance staff, promoting a culture of safety and precision. In conclusion, bull plug pressure rating is an essential component in ensuring the safety and efficacy of pipeline systems, particularly in high-pressure applications. By leveraging experience, adhering to established industrial standards, and partnering with credible suppliers, companies can maximize the performance and safety of their systems. Maintaining a focus on these fundamental aspects ensures that pipeline systems operate with the utmost integrity, protecting both personnel and the environment from potential hazards.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products