2 月 . 01, 2025 06:05

Back to list

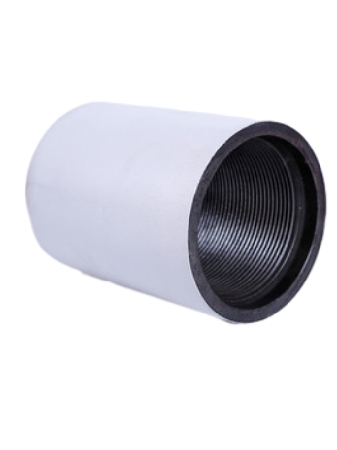

Crossover

The importance of effective sealing solutions in various industries cannot be overstated, and among the myriad options available, bullplugs have emerged as a critical component. Bullplugs, also known as pipe plugs, play a vital role in the oil and gas industry, construction, water treatment, and even aerospace, serving as an essential component to seal off pipes and prevent leaks. Offering an in-depth exploration of their utility and benefits provides a comprehensive understanding of their importance across different sectors.

Given the paramount importance of safety and efficiency in these applications, utilizing bullplugs from reputable manufacturers is essential. Investing in bullplugs that meet industry standards and specifications like ASME or ISO can significantly reduce risks and enhance safety protocols. Collaborating with manufacturers that offer customization based on specific needs can further optimize the use of bullplugs, ensuring a tailored fit for unique operational demands. In terms of maintenance, regular inspection of bullplugs is advised to ascertain their integrity. This involves checking for signs of wear, corrosion, or damage, which if unnoticed, could compromise the system’s functionality. Proper maintenance not only prolongs the lifespan of the bullplugs but also guarantees consistent performance, reinforcing the trustworthiness of the systems they are part of. Given the technical nature of bullplugs, partnering with experts for consultation and installation can augment the efficacy of these components. Specialists offer insights that not only fine-tune the selection process based on operational requirements but also provide ongoing support to address potential challenges post-installation. The eco-friendly aspect of bullplugs cannot be overlooked, as they play a role in minimizing environmental impact by preventing leaks that could lead to pollution. The implementation of bullplugs in line with environmental guidelines and standards underscores their contribution to sustainable practices across industries. In conclusion, bullplugs stand as a testament to the blend of engineering precision and practical necessity, forming a cornerstone in secure sealing applications across diverse industries. From their material construction to ease of installation and maintenance, each aspect underscores their indispensable role. As advancements continue, these components are poised to offer even greater adaptability and efficiency, proving their worth as essential tools in maintaining operational integrity and safety.

Given the paramount importance of safety and efficiency in these applications, utilizing bullplugs from reputable manufacturers is essential. Investing in bullplugs that meet industry standards and specifications like ASME or ISO can significantly reduce risks and enhance safety protocols. Collaborating with manufacturers that offer customization based on specific needs can further optimize the use of bullplugs, ensuring a tailored fit for unique operational demands. In terms of maintenance, regular inspection of bullplugs is advised to ascertain their integrity. This involves checking for signs of wear, corrosion, or damage, which if unnoticed, could compromise the system’s functionality. Proper maintenance not only prolongs the lifespan of the bullplugs but also guarantees consistent performance, reinforcing the trustworthiness of the systems they are part of. Given the technical nature of bullplugs, partnering with experts for consultation and installation can augment the efficacy of these components. Specialists offer insights that not only fine-tune the selection process based on operational requirements but also provide ongoing support to address potential challenges post-installation. The eco-friendly aspect of bullplugs cannot be overlooked, as they play a role in minimizing environmental impact by preventing leaks that could lead to pollution. The implementation of bullplugs in line with environmental guidelines and standards underscores their contribution to sustainable practices across industries. In conclusion, bullplugs stand as a testament to the blend of engineering precision and practical necessity, forming a cornerstone in secure sealing applications across diverse industries. From their material construction to ease of installation and maintenance, each aspect underscores their indispensable role. As advancements continue, these components are poised to offer even greater adaptability and efficiency, proving their worth as essential tools in maintaining operational integrity and safety.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products