2 月 . 02, 2025 04:55

Back to list

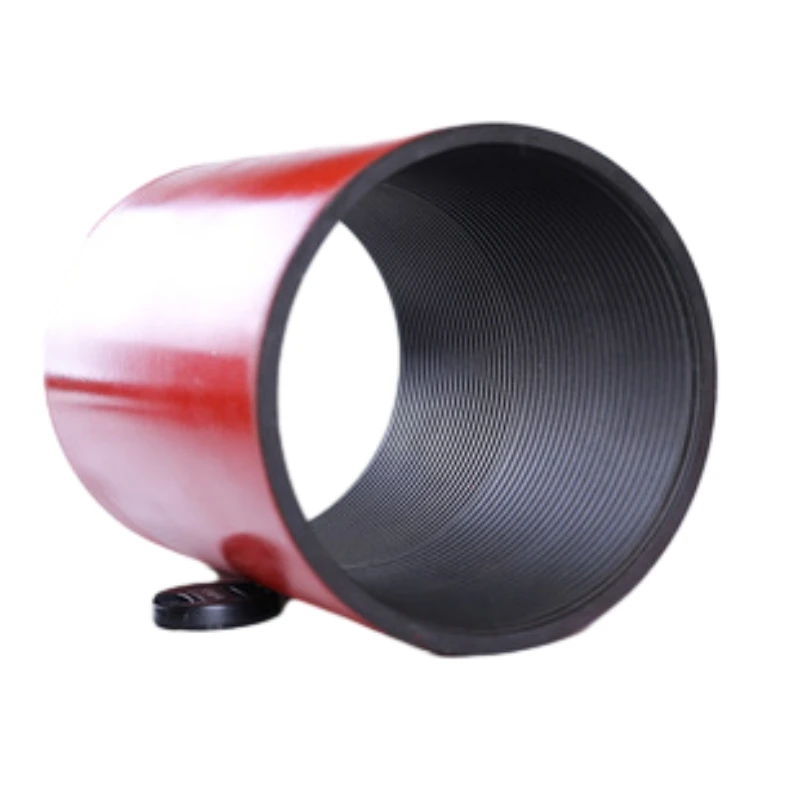

Tubing Pup Joint

The bull plug wellhead, a pivotal component in oil and gas extraction, serves as a critical piece of equipment in the capping and completion of wells. Its role in the preservation and management of well resources cannot be overstated, marking it as an essential part of the industry’s toolset.

Experts in wellhead technology often highlight the customization possibilities of bull plug wellheads. Tailored to the specific needs of individual wells, customized fittings enhance operational compatibility and reduce downtime. Experienced technicians and engineers collaborate closely in the customization process, taking into consideration factors such as the chemical composition of the extracted resources, pressures typical to the well, and the anticipated lifecycle of the operation. When selecting a bull plug wellhead, it's important for operators to consider a supplier's reputation and the adherence to international quality standards. Established manufacturers not only provide certifications and guarantees but also offer comprehensive aftersales services including maintenance, repair, and inspection. These services play a significant role in ensuring the long-term trustworthiness and reliability of the equipment. A carefully chosen bull plug wellhead can significantly impact the overall productivity and safety of drilling operations. By ensuring a perfect seal, maintaining pressure integrity, and preventing leaks, it stands as a testament to the progress in drilling technology and the ongoing commitment to safe and efficient resource extraction. In conclusion, the bull plug wellhead is more than just a simple piece in the drilling puzzle. It embodies the knowledge and expertise of countless engineers and represents a reliable partner in the quest for energy resources. Its design, adaptability, and functionality make it an indispensable asset in modern well operations. As advancements continue, it is anticipated that the design and functionality of bull plug wellheads will further evolve to meet the ever-changing demands of the oil and gas industry, maintaining their significance as both a tool of necessity and ingenuity.

Experts in wellhead technology often highlight the customization possibilities of bull plug wellheads. Tailored to the specific needs of individual wells, customized fittings enhance operational compatibility and reduce downtime. Experienced technicians and engineers collaborate closely in the customization process, taking into consideration factors such as the chemical composition of the extracted resources, pressures typical to the well, and the anticipated lifecycle of the operation. When selecting a bull plug wellhead, it's important for operators to consider a supplier's reputation and the adherence to international quality standards. Established manufacturers not only provide certifications and guarantees but also offer comprehensive aftersales services including maintenance, repair, and inspection. These services play a significant role in ensuring the long-term trustworthiness and reliability of the equipment. A carefully chosen bull plug wellhead can significantly impact the overall productivity and safety of drilling operations. By ensuring a perfect seal, maintaining pressure integrity, and preventing leaks, it stands as a testament to the progress in drilling technology and the ongoing commitment to safe and efficient resource extraction. In conclusion, the bull plug wellhead is more than just a simple piece in the drilling puzzle. It embodies the knowledge and expertise of countless engineers and represents a reliable partner in the quest for energy resources. Its design, adaptability, and functionality make it an indispensable asset in modern well operations. As advancements continue, it is anticipated that the design and functionality of bull plug wellheads will further evolve to meet the ever-changing demands of the oil and gas industry, maintaining their significance as both a tool of necessity and ingenuity.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products