2 月 . 12, 2025 21:23

Back to list

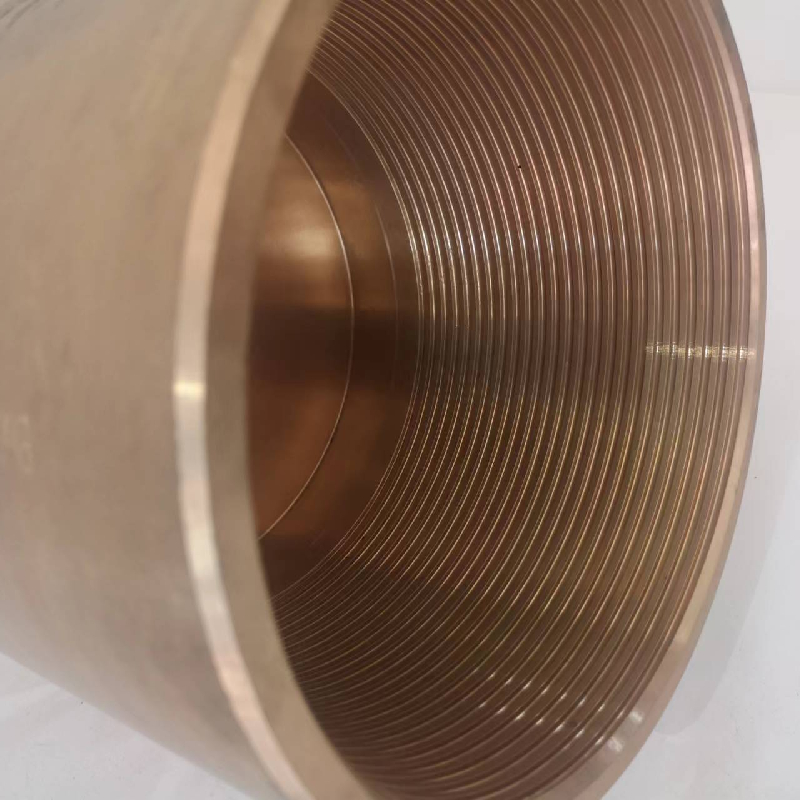

casing pup joint

In the oil and gas industry, efficient drilling operations depend on the proper integration of numerous components. Among these, casing pup joints play a critical role, providing flexibility and precision within the casing string. These vital connectors, although often understated, demand attention to detail and expertise to maximize their effectiveness, ensure well integrity, and enhance operational efficiency.

To amplify the authoritative voice on casing pup joints, insights from industry leaders and case studies highlight best practices and innovative approaches. Companies might showcase successful projects where the strategic use of pup joints resulted in enhanced well control, reduced downtime, and optimized resource management. Such examples not only demonstrate the tangible benefits but also reinforce the expertise of organizations within the sector. When discussing casing pup joints, it's essential to address the latest technological advancements and materials driving the industry's evolution. Advanced metallurgy techniques produce alloys with heightened resistance to corrosion, pressure, and temperature extremes, broadening the operational scope of casing pup joints. Digital technologies, including machine learning and predictive analytics, are also beginning to play a role in optimizing pup joint selection and maintenance schedules, thus reducing operational risks and improving efficiency. Investing in high-quality casing pup joints is a testament to a company's commitment to operational excellence and safety. By prioritizing products that offer durability, precision, and compatibility, operators lay a solid foundation for successful well management. Trust in these components is fortified by comprehensive quality assurances and ongoing research and development aimed at addressing future challenges in energy production. In conclusion, casing pup joints may be just one of many components in the complex machinery of oil and gas drilling, yet their impact is profound. A nuanced understanding of their roles, backed by authoritative insights and a commitment to quality, underscores their importance. As industry challenges evolve, so too must the strategies for optimizing these crucial components, ensuring they continue to serve as linchpins in safe, efficient, and successful drilling operations.

To amplify the authoritative voice on casing pup joints, insights from industry leaders and case studies highlight best practices and innovative approaches. Companies might showcase successful projects where the strategic use of pup joints resulted in enhanced well control, reduced downtime, and optimized resource management. Such examples not only demonstrate the tangible benefits but also reinforce the expertise of organizations within the sector. When discussing casing pup joints, it's essential to address the latest technological advancements and materials driving the industry's evolution. Advanced metallurgy techniques produce alloys with heightened resistance to corrosion, pressure, and temperature extremes, broadening the operational scope of casing pup joints. Digital technologies, including machine learning and predictive analytics, are also beginning to play a role in optimizing pup joint selection and maintenance schedules, thus reducing operational risks and improving efficiency. Investing in high-quality casing pup joints is a testament to a company's commitment to operational excellence and safety. By prioritizing products that offer durability, precision, and compatibility, operators lay a solid foundation for successful well management. Trust in these components is fortified by comprehensive quality assurances and ongoing research and development aimed at addressing future challenges in energy production. In conclusion, casing pup joints may be just one of many components in the complex machinery of oil and gas drilling, yet their impact is profound. A nuanced understanding of their roles, backed by authoritative insights and a commitment to quality, underscores their importance. As industry challenges evolve, so too must the strategies for optimizing these crucial components, ensuring they continue to serve as linchpins in safe, efficient, and successful drilling operations.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products