1 月 . 30, 2025 02:06

Back to list

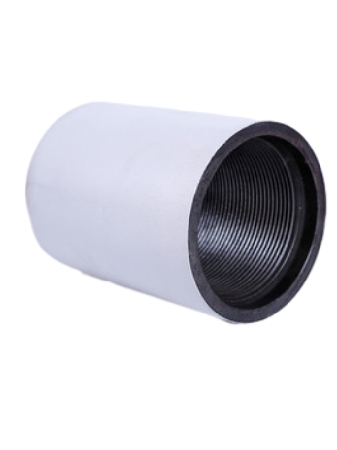

casing threads and couplings

Casing threads and couplings are essential components in the oil and gas industry, playing a crucial role in maintaining the integrity and efficacy of well operations. As experienced professionals in this field can attest, the expertise needed to select and utilize these components properly can significantly impact operational success and safety.

A high degree of authoritativeness is demanded from manufacturers of casing threads and couplings. Manufacturers must adhere to rigorous industry standards such as ISO and API for not only function but safety. Quality assurance processes often include non-destructive testing methods like ultrasonic testing or magnetic particle inspection to assure the threads and coupling's integrity before deployment. Trust in casing threads and couplings is built through a combination of product certification, engineering provenance, and field performance feedback. Operators incline towards manufacturers with longstanding industry experience and a history of reliable field deployment. They tend to prioritize products with a track record of performance in similar applications or recommendations from peer reviews. For those managing purchasing decisions within this domain, due diligence should involve comprehensive supplier evaluation, focusing on product innovation, compliance with international standards, and field performance history. Only through vigilant selection mirrored by operational expertise can projects mitigate the inherent risks involved in oil and gas extraction. The authenticity of field experience shared by industry veterans cannot be overstated when selecting casing threads and couplings. Insights from real-world applications provide an invaluable narrative that bolsters understanding of product limitations and potentials. Collaboration between engineers, procurement, and operational teams is essential to ensure that the casing components selected harmonize effectively with the project's technical requirements. By nurturing such informed, cooperative approaches, drilling operations can secure the trust and reliability demanded by the challenging and high-stakes oil and gas sector.

A high degree of authoritativeness is demanded from manufacturers of casing threads and couplings. Manufacturers must adhere to rigorous industry standards such as ISO and API for not only function but safety. Quality assurance processes often include non-destructive testing methods like ultrasonic testing or magnetic particle inspection to assure the threads and coupling's integrity before deployment. Trust in casing threads and couplings is built through a combination of product certification, engineering provenance, and field performance feedback. Operators incline towards manufacturers with longstanding industry experience and a history of reliable field deployment. They tend to prioritize products with a track record of performance in similar applications or recommendations from peer reviews. For those managing purchasing decisions within this domain, due diligence should involve comprehensive supplier evaluation, focusing on product innovation, compliance with international standards, and field performance history. Only through vigilant selection mirrored by operational expertise can projects mitigate the inherent risks involved in oil and gas extraction. The authenticity of field experience shared by industry veterans cannot be overstated when selecting casing threads and couplings. Insights from real-world applications provide an invaluable narrative that bolsters understanding of product limitations and potentials. Collaboration between engineers, procurement, and operational teams is essential to ensure that the casing components selected harmonize effectively with the project's technical requirements. By nurturing such informed, cooperative approaches, drilling operations can secure the trust and reliability demanded by the challenging and high-stakes oil and gas sector.

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products