Exploring the Concept of Coupling in Complex Systems and Its Implications

The Importance of Coupling Blanks in Industrial Applications

In the realm of industrial manufacturing, efficient operations hinge on the successful integration of numerous components and processes. One of the often-overlooked yet vital elements in this framework is the coupling blank. Coupling blanks serve as fundamental pieces that connect various machinery and equipment, ensuring smooth operation and minimizing downtime.

To understand the significance of coupling blanks, it is essential to recognize what they are. A coupling blank is essentially a piece of material, typically metal or plastic, that is used to create a connection between two components of a machine. This connection allows for the transmission of motion and power, making it a crucial element in numerous applications, from automotive to aerospace and heavy machinery.

One of the primary advantages of using coupling blanks is their ability to facilitate maintenance. By providing a replaceable connection point, these blanks allow for easier disassembly and reassembly of machinery. When a part wears down or becomes damaged, technicians can quickly swap out the coupling blank without needing to disconnect other vital elements of the system. This not only saves time but also reduces the potential for additional damage during maintenance procedures.

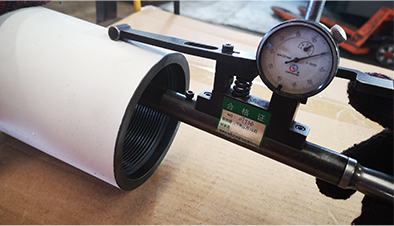

coupling blank

Moreover, coupling blanks contribute to the overall efficiency of operations. They allow for precise alignment between components, which is critical for the smooth transfer of energy. Misalignment can lead to increased wear and tear on machinery, reduced efficiency, and even catastrophic failures. By incorporating well-designed coupling blanks, manufacturers can enhance the reliability and performance of their equipment.

Another essential aspect of coupling blanks is their versatility. They can be produced in various shapes and sizes to accommodate different applications. This adaptability allows engineers to design systems that can handle a range of operational demands. For instance, in high-speed applications, specialized coupling blanks can be used to ensure that energy transfer occurs without a hitch, maintaining optimal performance levels.

Furthermore, modern advancements in material science have led to the development of specialized coupling blanks that offer enhanced durability and resistance to wear. Materials such as high-strength alloys and advanced polymers have been tailored to withstand the rigors of demanding industrial environments. This innovation not only extends the lifespan of the components but also contributes to the overall safety of the machinery.

In conclusion, coupling blanks play an indispensable role in the efficiency, safety, and maintainability of industrial systems. Their ability to facilitate maintenance, improve operational efficiency, and adapt to various applications makes them a cornerstone of modern manufacturing. As industries continue to evolve, the importance of coupling blanks will undoubtedly remain a critical factor in ensuring that machinery operates seamlessly and reliably. Investing in high-quality coupling blanks is not just a smart choice; it is a guarantee of enhanced performance and reduced operational costs in the long run.

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024