1 月 . 19, 2025 05:32

Back to list

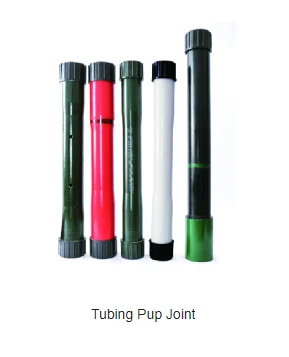

Tubing Pup Joint

Coupling tube fittings are critical components in numerous industries, including manufacturing, automotive, and aerospace. These small yet significant pieces ensure that fluids and gases flow smoothly through various systems, preventing leaks and maintaining efficiency. Understanding the intricacies of coupling tube fittings can significantly enhance operational efficiency, safety, and cost-effectiveness.

Furthermore, advancements in technology have led to the development of innovative coupling tube fittings designed for specific industry needs. Quick-connect fittings, for instance, minimize downtime by allowing for easy disconnection and reconnection during maintenance or system modifications. This feature is highly beneficial in industries where time is of the essence, offering efficiency without compromising on safety or performance. Trust in coupling tube fittings is built on a foundation of rigorous testing and certification. Reliable manufacturers subject their products to extensive testing under various conditions to certify their performance and safety. Certifications from recognized bodies not only testify to the quality of the fittings but also assure users of their reliability in critical applications. The role of coupling tube fittings in advancing sustainable practices is gaining attention in the engineering community. As industries strive to reduce their environmental footprint, choosing fittings fabricated from recyclable materials or those designed to minimize leaks contributes to greener operations. Stainless steel and certain plastics used in fittings can be recycled, aligning with initiatives aimed at reducing waste and conserving resources. In conclusion, coupling tube fittings, while often overlooked, are vital components in ensuring the smooth and efficient operation of countless industrial systems. Selecting the appropriate fitting, ensuring proper installation, and adhering to maintenance regimes are essential practices that enhance safety, performance, and sustainability. By understanding the expertise required in their application, industries can leverage these fittings to achieve greater efficiency, reliability, and environmental responsibility. As technology advances, coupling tube fittings will continue to evolve, offering even more solutions tailored to the ever-changing demands of various sectors.

Furthermore, advancements in technology have led to the development of innovative coupling tube fittings designed for specific industry needs. Quick-connect fittings, for instance, minimize downtime by allowing for easy disconnection and reconnection during maintenance or system modifications. This feature is highly beneficial in industries where time is of the essence, offering efficiency without compromising on safety or performance. Trust in coupling tube fittings is built on a foundation of rigorous testing and certification. Reliable manufacturers subject their products to extensive testing under various conditions to certify their performance and safety. Certifications from recognized bodies not only testify to the quality of the fittings but also assure users of their reliability in critical applications. The role of coupling tube fittings in advancing sustainable practices is gaining attention in the engineering community. As industries strive to reduce their environmental footprint, choosing fittings fabricated from recyclable materials or those designed to minimize leaks contributes to greener operations. Stainless steel and certain plastics used in fittings can be recycled, aligning with initiatives aimed at reducing waste and conserving resources. In conclusion, coupling tube fittings, while often overlooked, are vital components in ensuring the smooth and efficient operation of countless industrial systems. Selecting the appropriate fitting, ensuring proper installation, and adhering to maintenance regimes are essential practices that enhance safety, performance, and sustainability. By understanding the expertise required in their application, industries can leverage these fittings to achieve greater efficiency, reliability, and environmental responsibility. As technology advances, coupling tube fittings will continue to evolve, offering even more solutions tailored to the ever-changing demands of various sectors.

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products