2 月 . 18, 2025 04:47

Back to list

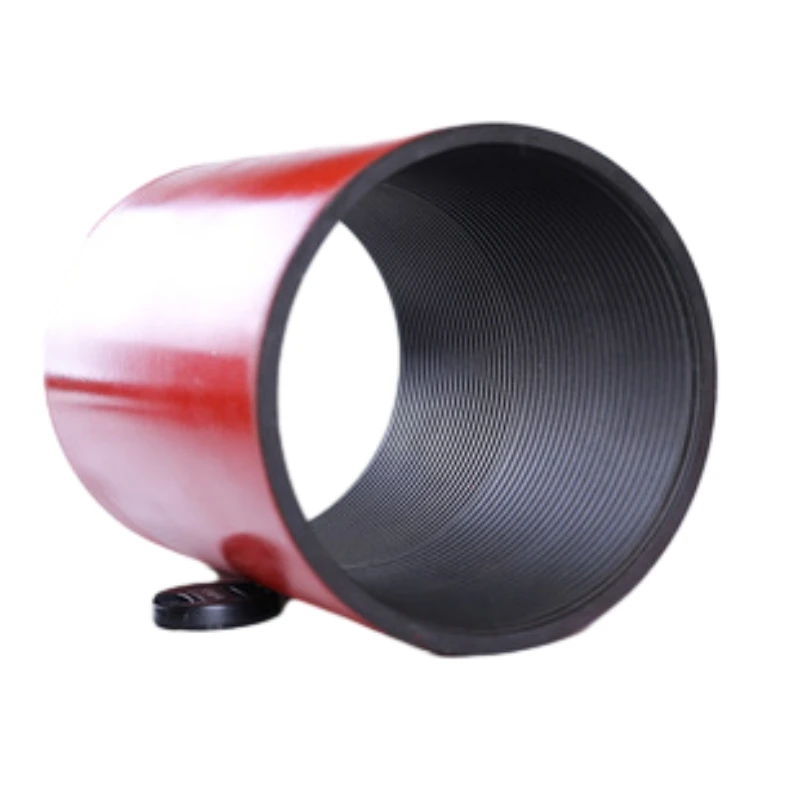

pasing pup joints

Pasing pup joints have long served as crucial components in the oil and gas industry, ensuring seamless connectivity within drilling operations. These joints might seem like modest pieces of equipment, yet they play a pivotal role in ensuring the effectiveness and safety of operations. As businesses continuously seek to optimize their operations, exploring the nuances of pasing pup joints can offer competitive advantages, both in operation efficiency and economic savings.

Deep expertise is integral in selecting the right pup joints for a given application. Matching the joint’s specifications to the environmental conditions and operational demands involves a careful assessment of pipeline pressure requirements, fluid characteristics, and overall system architecture. Here, collaboration with manufacturers or suppliers who demonstrate industry authority and comprehensive product knowledge is invaluable. Real-world experience even further emphasizes the importance of acquiring components from reputable manufacturers. High-authoritative manufacturers often subject their products to stringent testing procedures, verifying both compliance with industry standards and the operational assurance of the pup joints under realistic conditions. For an industry where precision and reliability are vital, such authoritative verification is essential. Trustworthiness in the pasing pup joint market often corresponds with transparency around manufacturing processes and ongoing customer support. A reputable supplier is not only forthcoming about the materials and processes involved but also offers continued support and guidance on best practices for installation and maintenance. Looking beyond product selection, the practical experience of installation and maintenance reveals the importance of technique and timing. Having personnel trained in precise installation procedures is vital. Improper installation can risk system integrity, leading to potentially costly failures. Meanwhile, systematic maintenance ensures that pasing pup joints function optimally over their lifespan. Regular inspections and proactive replacements prevent unexpected downtimes and maintain system health. In sum, pasing pup joints are more than mere connective components; they are foundational to the safe, efficient, and economic functioning of drilling operations. The interplay of experience, expertise, authority, and trustworthiness defines their successful application. By focusing on high-quality materials, precise customization, reliable manufacturers, and careful maintenance, businesses in the oil and gas sector can capitalize on the benefits these indispensable tools offer. As the industry continues to evolve, the strategic integration and updating of pup joints will inevitably remain a core aspect of operational optimization.

Deep expertise is integral in selecting the right pup joints for a given application. Matching the joint’s specifications to the environmental conditions and operational demands involves a careful assessment of pipeline pressure requirements, fluid characteristics, and overall system architecture. Here, collaboration with manufacturers or suppliers who demonstrate industry authority and comprehensive product knowledge is invaluable. Real-world experience even further emphasizes the importance of acquiring components from reputable manufacturers. High-authoritative manufacturers often subject their products to stringent testing procedures, verifying both compliance with industry standards and the operational assurance of the pup joints under realistic conditions. For an industry where precision and reliability are vital, such authoritative verification is essential. Trustworthiness in the pasing pup joint market often corresponds with transparency around manufacturing processes and ongoing customer support. A reputable supplier is not only forthcoming about the materials and processes involved but also offers continued support and guidance on best practices for installation and maintenance. Looking beyond product selection, the practical experience of installation and maintenance reveals the importance of technique and timing. Having personnel trained in precise installation procedures is vital. Improper installation can risk system integrity, leading to potentially costly failures. Meanwhile, systematic maintenance ensures that pasing pup joints function optimally over their lifespan. Regular inspections and proactive replacements prevent unexpected downtimes and maintain system health. In sum, pasing pup joints are more than mere connective components; they are foundational to the safe, efficient, and economic functioning of drilling operations. The interplay of experience, expertise, authority, and trustworthiness defines their successful application. By focusing on high-quality materials, precise customization, reliable manufacturers, and careful maintenance, businesses in the oil and gas sector can capitalize on the benefits these indispensable tools offer. As the industry continues to evolve, the strategic integration and updating of pup joints will inevitably remain a core aspect of operational optimization.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products