2 月 . 13, 2025 15:10

Back to list

pipe bull plug

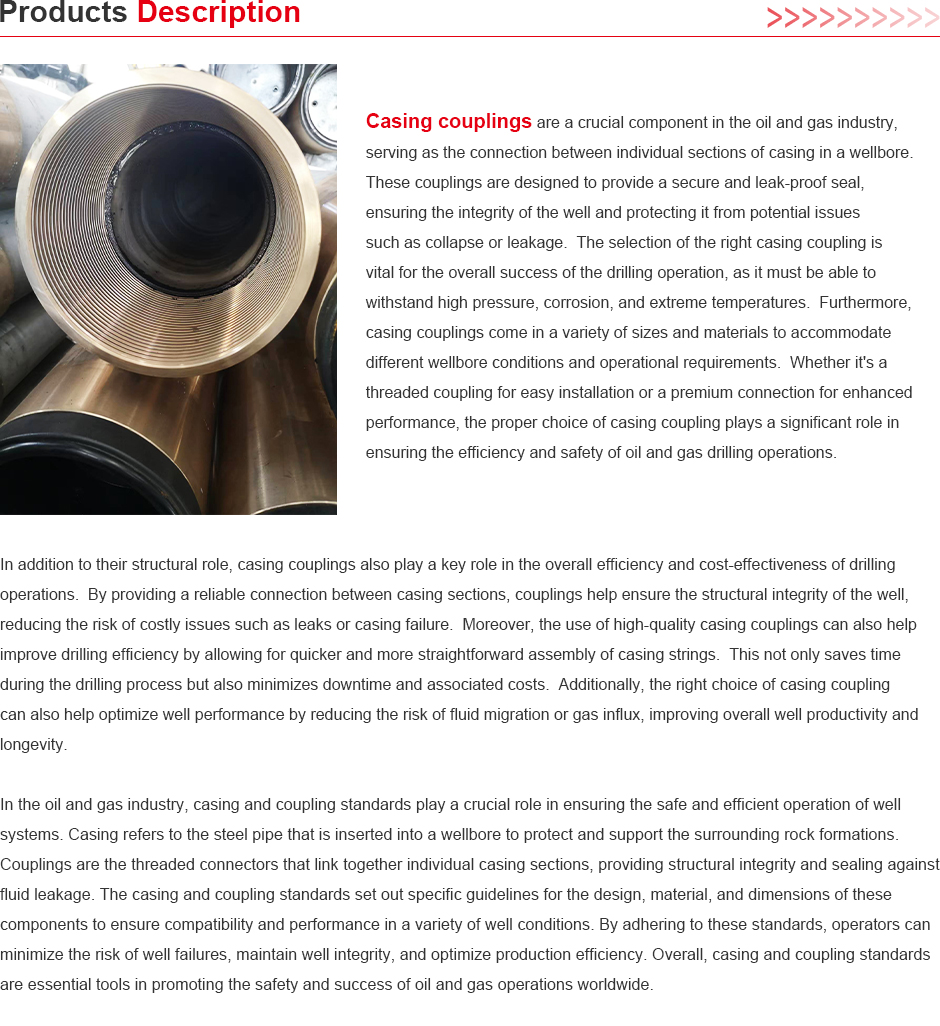

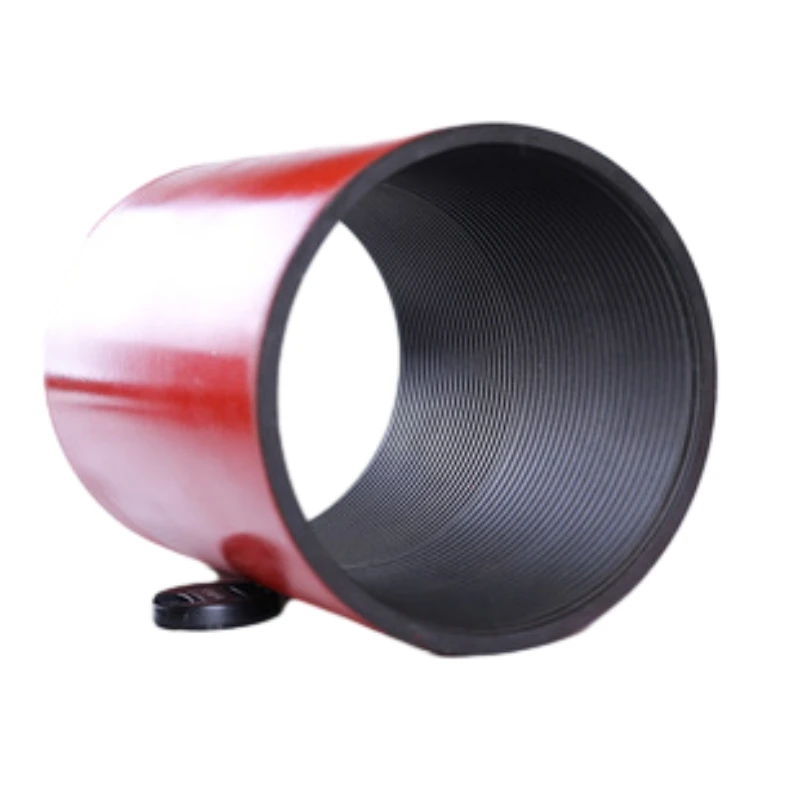

Pipe bull plugs, often considered essential components in various industrial applications, are designed to temporarily or permanently seal the end of a pipe. Whether in oil and gas, chemical processing, or hydraulic systems, selecting the right bull plug can be crucial for maintaining system integrity and efficiency. This informative guide draws from extensive industry expertise to shed light on the critical considerations when choosing and using pipe bull plugs.

Choosing the Right Supplier Selecting a reputable supplier with a proven track record in manufacturing high-quality pipe bull plugs can significantly influence the efficiency and safety of your operations. Suppliers with ISO certifications or those that adhere to global standards often assure better quality control and product consistency. Additionally, considering suppliers who offer customization options can be beneficial, allowing for the production of bull plugs tailored to specific requirements, such as unique pressure ratings or material specifications. Partnering with such suppliers contributes to reducing downtime and enhancing system performance through bespoke solutions. Environmental and Safety Standards As industries strive towards sustainability, attention is shifting towards ensuring that all components, including pipe bull plugs, adhere to environmental and safety regulations. Opting for bull plugs that are manufactured using eco-friendly processes and materials reduces the environmental impact and aligns with global sustainability goals. Furthermore, complying with industry-specific safety standards mitigates risks associated with leaks or failures. Manufacturers often conduct rigorous testing to ensure that their products meet safety criteria, providing peace of mind and trustworthiness to end-users. Future Perspectives and Developments The landscape of pipe bull plugs is continuously evolving, driven by technological advancements and increasing industry demands. Future developments may likely focus on enhancing durability, improving resistance to extreme conditions, and integrating smart technology for better monitoring and maintenance. Innovations such as self-sealing mechanisms or material enhancements for increased lifespan are promising areas of development. These advancements will not only boost the performance of existing systems but also pave the way for new applications in unexplored industries. Ultimately, the strategic use of pipe bull plugs, underpinned by expertise and tailored solutions, remains critical in meeting industrial demands efficiently and sustainably. As technology progresses, staying informed about the latest developments ensures that businesses can leverage these innovations to maintain a competitive edge in their respective fields.

Choosing the Right Supplier Selecting a reputable supplier with a proven track record in manufacturing high-quality pipe bull plugs can significantly influence the efficiency and safety of your operations. Suppliers with ISO certifications or those that adhere to global standards often assure better quality control and product consistency. Additionally, considering suppliers who offer customization options can be beneficial, allowing for the production of bull plugs tailored to specific requirements, such as unique pressure ratings or material specifications. Partnering with such suppliers contributes to reducing downtime and enhancing system performance through bespoke solutions. Environmental and Safety Standards As industries strive towards sustainability, attention is shifting towards ensuring that all components, including pipe bull plugs, adhere to environmental and safety regulations. Opting for bull plugs that are manufactured using eco-friendly processes and materials reduces the environmental impact and aligns with global sustainability goals. Furthermore, complying with industry-specific safety standards mitigates risks associated with leaks or failures. Manufacturers often conduct rigorous testing to ensure that their products meet safety criteria, providing peace of mind and trustworthiness to end-users. Future Perspectives and Developments The landscape of pipe bull plugs is continuously evolving, driven by technological advancements and increasing industry demands. Future developments may likely focus on enhancing durability, improving resistance to extreme conditions, and integrating smart technology for better monitoring and maintenance. Innovations such as self-sealing mechanisms or material enhancements for increased lifespan are promising areas of development. These advancements will not only boost the performance of existing systems but also pave the way for new applications in unexplored industries. Ultimately, the strategic use of pipe bull plugs, underpinned by expertise and tailored solutions, remains critical in meeting industrial demands efficiently and sustainably. As technology progresses, staying informed about the latest developments ensures that businesses can leverage these innovations to maintain a competitive edge in their respective fields.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products