2 月 . 08, 2025 06:14

Back to list

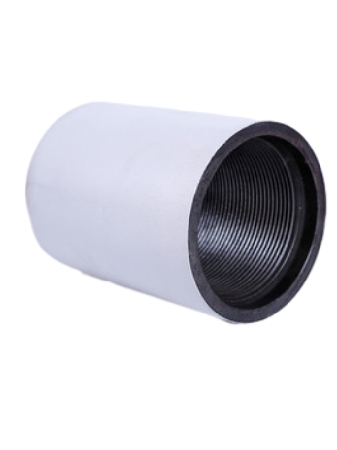

Tubing Coupling

Pipe mills play a crucial role in various industries by transforming raw materials into high-quality pipes used for construction, oil and gas transport, and water systems. With decades of technological advancement and rigorous quality standards, the pipe manufacturing industry has evolved significantly. A closer look reveals the characteristics that make a modern pipe mill an epitome of efficiency and reliability.

A notable aspect that enhances the trustworthiness of pipe mills is their traceability systems. Top-tier factories have implemented advanced tracking systems that document the journey of a pipe from raw material procurement to final dispatch. This level of transparency allows clients to have insights into the manufacturing process, enhancing accountability and ensuring the adherence to agreed specifications. Such transparency fosters long-lasting business relationships and confidence in the products delivered. Real-world experience underscores the importance of skilled labor working in conjunction with innovative technology. The seamless fusion of human expertise and automated processes is visible in every pipe produced. Skilled technicians and engineers, seasoned through years of hands-on experience, are indispensable in overseeing operations, identifying discrepancies, and ensuring the optimal functionality of equipment. Their role is pivotal, as their insights contribute to the fine-tuning of processes that an automated system might overlook. Environmental considerations have also gained prominence in the operational ethos of pipe mills. Modern facilities emphasize sustainable practices, utilizing waste reduction methods and energy-efficient technologies. From recycling scrap material to optimizing fuel usage, these initiatives echo a responsibility towards environmental stewardship, aligning with global efforts to minimize industrial footprints. In conclusion, the evolution of pipe mills embodies a synergy of technology, expertise, adherence to global standards, and a commitment to sustainable practices. They serve as a cornerstone to industries that rely on precision-engineered components, ensuring safety, efficiency, and durability. This amalgamation of factors not only bolsters the credibility and reliability of contemporary pipe mills but also underpins their indispensable role in modern infrastructure development.

A notable aspect that enhances the trustworthiness of pipe mills is their traceability systems. Top-tier factories have implemented advanced tracking systems that document the journey of a pipe from raw material procurement to final dispatch. This level of transparency allows clients to have insights into the manufacturing process, enhancing accountability and ensuring the adherence to agreed specifications. Such transparency fosters long-lasting business relationships and confidence in the products delivered. Real-world experience underscores the importance of skilled labor working in conjunction with innovative technology. The seamless fusion of human expertise and automated processes is visible in every pipe produced. Skilled technicians and engineers, seasoned through years of hands-on experience, are indispensable in overseeing operations, identifying discrepancies, and ensuring the optimal functionality of equipment. Their role is pivotal, as their insights contribute to the fine-tuning of processes that an automated system might overlook. Environmental considerations have also gained prominence in the operational ethos of pipe mills. Modern facilities emphasize sustainable practices, utilizing waste reduction methods and energy-efficient technologies. From recycling scrap material to optimizing fuel usage, these initiatives echo a responsibility towards environmental stewardship, aligning with global efforts to minimize industrial footprints. In conclusion, the evolution of pipe mills embodies a synergy of technology, expertise, adherence to global standards, and a commitment to sustainable practices. They serve as a cornerstone to industries that rely on precision-engineered components, ensuring safety, efficiency, and durability. This amalgamation of factors not only bolsters the credibility and reliability of contemporary pipe mills but also underpins their indispensable role in modern infrastructure development.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products