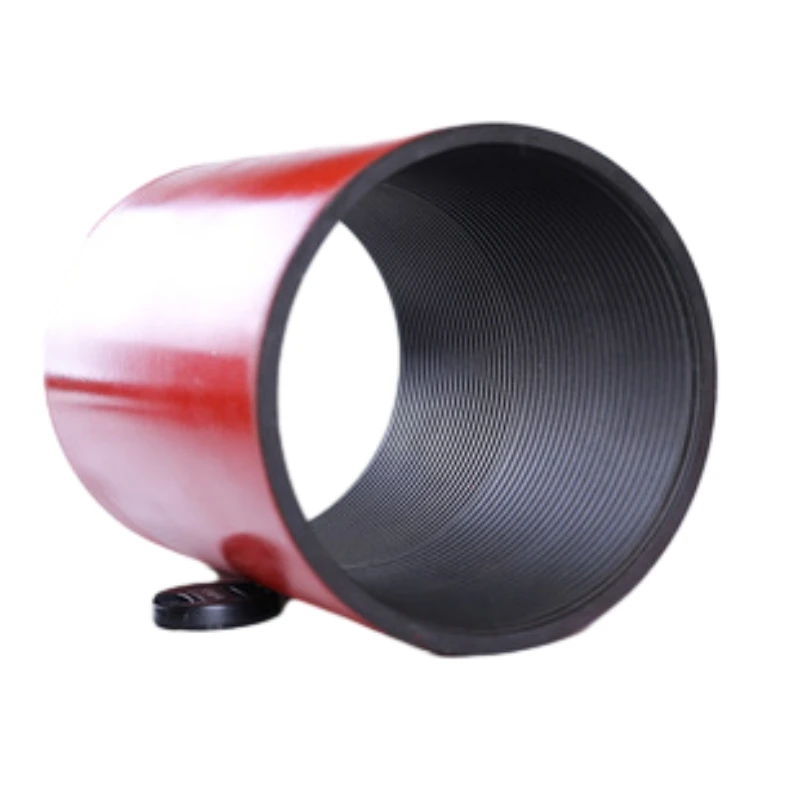

pipe threader

Understanding Pipe Threaders A Comprehensive Guide

When it comes to plumbing and various industrial applications, the need for reliable fittings and connections is paramount. One of the essential tools that facilitate these connections is the pipe threader. This article will delve into the types, uses, and benefits of pipe threaders, highlighting their importance in ensuring secure and leak-proof piping systems.

What is a Pipe Threader?

A pipe threader is a specialized tool used to cut and create threads on the ends of pipes. This threading allows for pipes to be screwed together, forming a tight seal that prevents leaks. These tools are critical in plumbing, construction, and even automotive applications, where robust fluid transport systems are required.

Types of Pipe Threaders

1. Manual Pipe Threaders As the name suggests, these threaders require manual effort to operate. They typically consist of a die head and a handle that the user turns to cut threads. Manual threaders are more affordable and are often used by DIY enthusiasts or for smaller projects.

2. Electric Pipe Threaders These power-operated tools significantly reduce the effort and time needed to create threads. Electric threaders come with a motor that drives the die heads, making them ideal for larger pipes or for professionals who require efficiency and speed.

3. Hydraulic Pipe Threaders For heavy-duty applications, hydraulic pipe threaders offer immense power and precision. They are commonly used in industrial settings where large-diameter pipes must be threaded.

4. Threading Machines These are advanced units that can thread multiple sizes of pipes with high precision and speed. They are suitable for factories and large-scale manufacturing operations.

Uses of Pipe Threaders

Pipe threaders play a pivotal role in various applications, among them

pipe threader

- Plumbing Essential for connecting pipes in residential and commercial plumbing systems. - HVAC Used in heating, ventilation, and air conditioning systems, where ductwork requires secure connections. - Oil and Gas Employed in the installation of pipelines for transporting oil, gas, and other fluids. - Manufacturing Integral in producing and assembling machinery that relies on piped connections for fluid transport.

Benefits of Using a Pipe Threader

The advantages of using pipe threaders are numerous

1. Precision Pipe threaders produce clean, accurate threads that ensure a perfect fit. This precision is crucial in preventing leaks and maintaining the integrity of the piping system.

2. Speed Electric and hydraulic pipe threaders can create threads much faster than manual methods, which can ultimately save time and labor costs on large projects.

3. Versatility Many pipe threaders can accommodate a range of pipe sizes and types, from small residential pipes to large industrial ones.

4. Durability High-quality pipe threaders are built to withstand the rigors of frequent use, making them a worthwhile investment for professionals.

5. Safety Properly threaded pipes reduce the likelihood of leaks and failures, ensuring a safer environment in industrial and residential applications.

Conclusion

In conclusion, pipe threaders are indispensable tools in the world of plumbing and industrial applications. Whether manual, electric, or hydraulic, these tools enable users to create secure, precise thread connections with ease. Their importance cannot be overstated, as they contribute to the efficiency and reliability of piping systems across industries. For anyone working with pipes, understanding the capabilities and proper usage of pipe threaders is essential for achieving optimal results and maintaining safe operations.

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024