1 月 . 22, 2025 02:13

Back to list

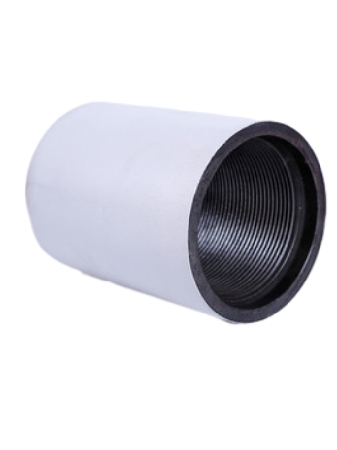

pup joint drilling

Pup joints play a critical role in the drilling industry, serving as essential components that ensure the seamless and efficient performance of deep drilling operations. A pup joint refers to a short length of pipe used in drilling to adjust the length of tubular strings to their precise requirements. This document delves into the detailed understanding of pup joints, emphasizing their importance, variations, and applications within the oil and gas industry.

The versatility of pup joints extends beyond mere length adjustments. They serve crucial functions in drill string evaluation, facilitating the attachment of various downhole tools and sensors. This adaptability allows for real-time data collection and analysis, which is vital for optimizing drilling operations and making informed decisions. Such functionality aligns with the growing demand for smart drilling solutions, integrating technology with traditional drilling practices to enhance efficiency and effectiveness. Moreover, pup joints contribute significantly to the economic sustainability of drilling projects. By enabling precise adjustments and reducing the need for extensive modifications, these joints decrease downtime and increase operational predictability. The cost savings associated with reduced labor, expedited setups, and minimized risk of failures contribute to the overall profitability of drilling endeavors. Manufacturers of pup joints continuously strive to innovate, exploring new materials and construction techniques to further enhance performance. Advances in metallurgy and engineering have introduced new alloys and coatings that improve the corrosion resistance and longevity of pup joints, adding to their value proposition. Collaborating with engineers and field experts, manufacturers ensure that the latest technological advancements are incorporated into pup joint designs, keeping them at the forefront of industry standards. In summary, pup joints are indispensable components within the drilling industry, bridging the gap between operational flexibility and safety. Their precision, adaptability, and robust construction embody the characteristics of high-quality drilling equipment. As the industry evolves, the integration of advanced technologies and materials continues to fortify pup joints' position as pivotal elements in successful drilling operations. By emphasizing the expertise, authority, and trustworthiness associated with their use, pup joints ensure that drilling endeavors can proceed with confidence and success.

The versatility of pup joints extends beyond mere length adjustments. They serve crucial functions in drill string evaluation, facilitating the attachment of various downhole tools and sensors. This adaptability allows for real-time data collection and analysis, which is vital for optimizing drilling operations and making informed decisions. Such functionality aligns with the growing demand for smart drilling solutions, integrating technology with traditional drilling practices to enhance efficiency and effectiveness. Moreover, pup joints contribute significantly to the economic sustainability of drilling projects. By enabling precise adjustments and reducing the need for extensive modifications, these joints decrease downtime and increase operational predictability. The cost savings associated with reduced labor, expedited setups, and minimized risk of failures contribute to the overall profitability of drilling endeavors. Manufacturers of pup joints continuously strive to innovate, exploring new materials and construction techniques to further enhance performance. Advances in metallurgy and engineering have introduced new alloys and coatings that improve the corrosion resistance and longevity of pup joints, adding to their value proposition. Collaborating with engineers and field experts, manufacturers ensure that the latest technological advancements are incorporated into pup joint designs, keeping them at the forefront of industry standards. In summary, pup joints are indispensable components within the drilling industry, bridging the gap between operational flexibility and safety. Their precision, adaptability, and robust construction embody the characteristics of high-quality drilling equipment. As the industry evolves, the integration of advanced technologies and materials continues to fortify pup joints' position as pivotal elements in successful drilling operations. By emphasizing the expertise, authority, and trustworthiness associated with their use, pup joints ensure that drilling endeavors can proceed with confidence and success.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products