PUP Joint Specifications Overview and Key Considerations for Effective Implementation

Understanding PUP Joint Specifications Key Considerations for Optimal Performance

In the realm of mechanical engineering, the importance of precise specifications for joints, especially in the context of PUP (Polyurethane Polymer) joints, cannot be overstated. PUP joints are widely recognized for their durability, flexibility, and resilience, making them ideal for various applications ranging from automotive to construction industries. Understanding the specifications and their implications is crucial for ensuring the optimal performance of these joints.

Understanding PUP Joint Specifications Key Considerations for Optimal Performance

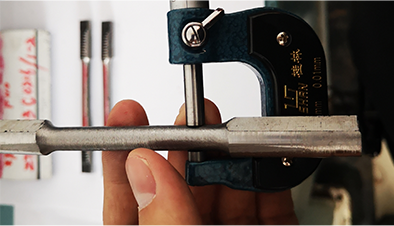

Dimensions are another paramount consideration. PUP joint specifications dictate precise measurements to ensure a perfect fit and alignment within mechanical assemblies. An improperly sized joint can lead to excessive wear, failure, or misalignment, significantly impacting the equipment's efficiency and reliability. Engineers must adhere to manufacturer specifications regarding outer diameter, inner diameter, and width to maintain the integrity of the joint.

pup joint specifications

Load capacity is equally important in the specification of PUP joints. Each joint is designed to endure specific loads, both static and dynamic. Understanding the load-bearing capabilities is essential for selecting the right joint for a particular application. Exceeding these limits can lead to premature failure, compromising the overall structure. Hence, engineers must assess the operational conditions to ascertain whether the specified joint meets the necessary load requirements.

Moreover, environmental resistance is a critical factor in the longevity of PUP joints. Factors such as temperature fluctuations, exposure to chemicals, and moisture can significantly impact joint performance. Advanced formulations of polyurethane can enhance resistance to these elements, thereby extending the joint's service life. Specifications should therefore include performance metrics under varying environmental conditions to guide users in selecting the best joint for their needs.

In conclusion, PUP joint specifications are integral to the successful implementation and longevity of mechanical systems. By focusing on material properties, dimensional accuracy, load capacity, and environmental resistance, engineers can ensure that they select the most appropriate joints for their applications. Ultimately, attention to these specifications not only enhances performance but also contributes to the overall safety and reliability of engineered systems.

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024