1 月 . 31, 2025 05:20

Back to list

Crossover

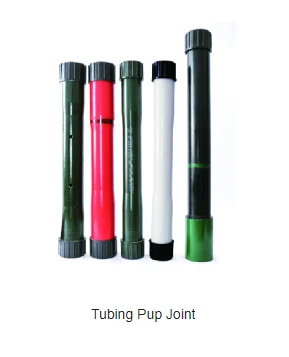

Pup joint tubing plays a pivotal role in the operational efficiency and functionality of oil and gas drilling processes. Designed to adjust the length of the drill string or piping system, pup joints are short sections of pipe that come in various lengths and diameters, allowing for precise customization in drilling operations. In industries where precision and efficiency are paramount, understanding the nuances and applications of pup joint tubing can yield significant benefits.

Trustworthiness, both in the product and the personnel handling it, forms the foundation of successful implementation. Field professionals must not only be able to trust their equipment, knowing it will perform under the specified conditions, but also the judgments and recommendations of their peers and suppliers. This trust is built through consistent performance, thorough testing, and a transparent supply chain that values long-term relationships over immediate financial gains. Practical experiences from the field validate the significance of high-quality pup joint tubing. For instance, case studies from various drilling sites demonstrate that the use of reliable tubing results in fewer interruptions and a smoother overall operation. Reports of reduced equipment wear and tear, thanks to better fitting and more appropriate selection of joints, reinforce the importance of choosing the right products and having skilled operators. In essence, the selection and use of pup joint tubing encapsulate the core values of Experience, Expertise, Authoritativeness, and Trustworthiness. By making informed decisions based on real-world applications and a deep understanding of the product, industry professionals can significantly enhance the efficiency and safety of their operations. As the energy sector continues to evolve, the importance of such informed decisions only continues to grow, underscoring the need for continuous learning and quality assurance in the selection of drilling equipment.

Trustworthiness, both in the product and the personnel handling it, forms the foundation of successful implementation. Field professionals must not only be able to trust their equipment, knowing it will perform under the specified conditions, but also the judgments and recommendations of their peers and suppliers. This trust is built through consistent performance, thorough testing, and a transparent supply chain that values long-term relationships over immediate financial gains. Practical experiences from the field validate the significance of high-quality pup joint tubing. For instance, case studies from various drilling sites demonstrate that the use of reliable tubing results in fewer interruptions and a smoother overall operation. Reports of reduced equipment wear and tear, thanks to better fitting and more appropriate selection of joints, reinforce the importance of choosing the right products and having skilled operators. In essence, the selection and use of pup joint tubing encapsulate the core values of Experience, Expertise, Authoritativeness, and Trustworthiness. By making informed decisions based on real-world applications and a deep understanding of the product, industry professionals can significantly enhance the efficiency and safety of their operations. As the energy sector continues to evolve, the importance of such informed decisions only continues to grow, underscoring the need for continuous learning and quality assurance in the selection of drilling equipment.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products