2 月 . 15, 2025 14:41

Back to list

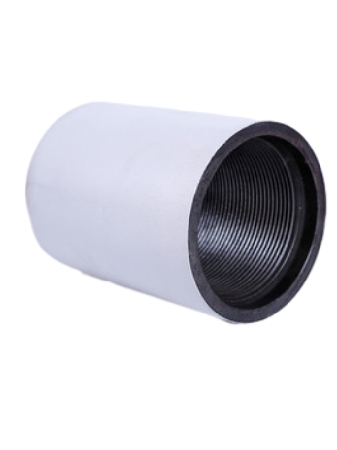

seamless pipe

Seamless pipes have quietly revolutionized industries ranging from oil and gas to construction and beyond. Though often overshadowed by their welded counterparts, seamless pipes offer unique advantages that ensure their relevance in various industrial applications. With rising demands for durability and reliability, industries increasingly lean on seamless solutions that only these pipes can fulfill.

The HVAC (Heating, Ventilation, and Air Conditioning) industry also utilizes seamless pipes that excel in resisting wear and corrosion. Ideal for high-pressure scenarios, the pipes facilitate efficient heat transfer and air circulation, vital for maintaining optimal environmental conditions. The combination of expertise in material selection and seamless manufacturing practices ensures HVAC systems operate with peak efficiency and minimal maintenance, fulfilling both residential and commercial needs. The authoritative edge of seamless pipes is evident in rigorous quality standards and certifications they must meet. As industrial demands flex and grow, seamless pipe manufacturing follows stringent protocols to ensure conformity with global standards. This includes ISO certification processes that verify product consistency and reliability. Trustworthiness shines as seamless pipes are scrutinized, tested, and approved for use in demanding conditions where safety is paramount. Real-world experiences convey the trust industries place in seamless pipes. Countless stories reflect how these pipes perform under pressure—not just mechanically but also in reliability assessments. Long-term investments in seamless infrastructure translate into lower maintenance costs and extended service life, making a strong economic case for their integration. The seamless pipe industry continues to evolve, with innovations that further bolster its status as an indispensable resource. Technological advancements in materials, like alloy enhancements, refine their capabilities, extending their functional range. As environmental considerations become more prevalent, the role of seamless pipes in developing sustainable practices cannot be overstated. Advances in manufacturing processes aim to reduce production emissions, contributing to eco-friendly solutions while maintaining unparalleled quality. Seamless pipes have paved the way for technological and structural advancements across industries. They embody a blend of experience-backed reliability, unsurpassed expertise in manufacturing, authoritative standards, and the trust of numerous sectors. This fourfold assurance makes seamless pipes not just a product but a pivotal tool driving industries towards an innovative and resilient future.

The HVAC (Heating, Ventilation, and Air Conditioning) industry also utilizes seamless pipes that excel in resisting wear and corrosion. Ideal for high-pressure scenarios, the pipes facilitate efficient heat transfer and air circulation, vital for maintaining optimal environmental conditions. The combination of expertise in material selection and seamless manufacturing practices ensures HVAC systems operate with peak efficiency and minimal maintenance, fulfilling both residential and commercial needs. The authoritative edge of seamless pipes is evident in rigorous quality standards and certifications they must meet. As industrial demands flex and grow, seamless pipe manufacturing follows stringent protocols to ensure conformity with global standards. This includes ISO certification processes that verify product consistency and reliability. Trustworthiness shines as seamless pipes are scrutinized, tested, and approved for use in demanding conditions where safety is paramount. Real-world experiences convey the trust industries place in seamless pipes. Countless stories reflect how these pipes perform under pressure—not just mechanically but also in reliability assessments. Long-term investments in seamless infrastructure translate into lower maintenance costs and extended service life, making a strong economic case for their integration. The seamless pipe industry continues to evolve, with innovations that further bolster its status as an indispensable resource. Technological advancements in materials, like alloy enhancements, refine their capabilities, extending their functional range. As environmental considerations become more prevalent, the role of seamless pipes in developing sustainable practices cannot be overstated. Advances in manufacturing processes aim to reduce production emissions, contributing to eco-friendly solutions while maintaining unparalleled quality. Seamless pipes have paved the way for technological and structural advancements across industries. They embody a blend of experience-backed reliability, unsurpassed expertise in manufacturing, authoritative standards, and the trust of numerous sectors. This fourfold assurance makes seamless pipes not just a product but a pivotal tool driving industries towards an innovative and resilient future.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products