2 月 . 01, 2025 03:41

Back to list

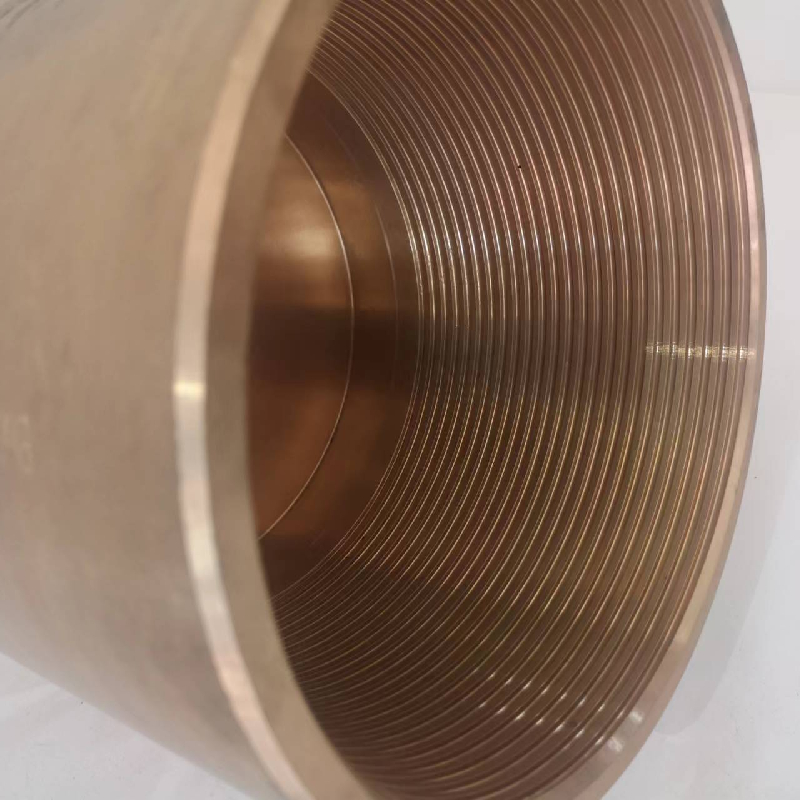

seating nipple

Exploring the Dynamic Role of Seating Nipples in Oil and Gas Industry An Insightful Review

Innovative enhancements in seating nipple designs are continually evolving, influenced by advances in materials science and the industry's ever-increasing demands for efficiency and safety. The adoption of state-of-the-art technologies in the manufacture of these components echoes the industry's priorities in innovation and sustainability. Such technological embodiments not only affirm seating nipples' crucial role but also enhance their functional reliability in significantly complex downhole scenarios. In addition to being strategically essential components, seating nipples are a subject of significant authority in the realm of well integrity management. As wells age, maintaining their integrity becomes imperative to prevent environmental hazards and optimize production levels. Seating nipples, by facilitating the strategic placement of monitoring and control equipment, enable operators to continuously assess and manage well conditions, thereby ensuring operational safety and compliance with environmental regulations. For operators seeking expert guidance on maximizing the practicality of seating nipples, seeking professional consultation and collaboration with leading manufacturers can enhance outcomes. These entities offer invaluable insights into the latest technologies and material adaptations critical for optimizing seating nipple deployment. Moreover, trustworthiness is paramount in the oil and gas industry, and seating nipples are no exception. The reliability of these components is vital in maintaining stakeholder confidence. Reputable manufacturers often provide certifications and documentation that confirm the adherence of seating nipples to stringent industry and safety standards, reinforcing their dependability. In conclusion, seating nipples are a cornerstone in oil and gas operations, integral to facilitating efficient and safe extraction processes. Professionals navigating the complexities of oil well completion are encouraged to draw upon their expertise and the authoritative resources available to optimize the utilization of these components. By doing so, they ensure enhanced operational productivity, maintain well integrity, and uphold the environmental and safety standards essential to modern energy production. As challenges in resource extraction evolve, the role of seating nipples will undeniably continue to resonate within the oil and gas sector, underscoring the importance of ongoing innovation and professional expertise.

Innovative enhancements in seating nipple designs are continually evolving, influenced by advances in materials science and the industry's ever-increasing demands for efficiency and safety. The adoption of state-of-the-art technologies in the manufacture of these components echoes the industry's priorities in innovation and sustainability. Such technological embodiments not only affirm seating nipples' crucial role but also enhance their functional reliability in significantly complex downhole scenarios. In addition to being strategically essential components, seating nipples are a subject of significant authority in the realm of well integrity management. As wells age, maintaining their integrity becomes imperative to prevent environmental hazards and optimize production levels. Seating nipples, by facilitating the strategic placement of monitoring and control equipment, enable operators to continuously assess and manage well conditions, thereby ensuring operational safety and compliance with environmental regulations. For operators seeking expert guidance on maximizing the practicality of seating nipples, seeking professional consultation and collaboration with leading manufacturers can enhance outcomes. These entities offer invaluable insights into the latest technologies and material adaptations critical for optimizing seating nipple deployment. Moreover, trustworthiness is paramount in the oil and gas industry, and seating nipples are no exception. The reliability of these components is vital in maintaining stakeholder confidence. Reputable manufacturers often provide certifications and documentation that confirm the adherence of seating nipples to stringent industry and safety standards, reinforcing their dependability. In conclusion, seating nipples are a cornerstone in oil and gas operations, integral to facilitating efficient and safe extraction processes. Professionals navigating the complexities of oil well completion are encouraged to draw upon their expertise and the authoritative resources available to optimize the utilization of these components. By doing so, they ensure enhanced operational productivity, maintain well integrity, and uphold the environmental and safety standards essential to modern energy production. As challenges in resource extraction evolve, the role of seating nipples will undeniably continue to resonate within the oil and gas sector, underscoring the importance of ongoing innovation and professional expertise.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products