Stainless Steel Pipe Coupling for Efficient Fluid Connection and Durability

SS Pipe Coupling An Essential Component in Modern Piping Systems

In the realm of modern engineering and construction, the importance of reliable and efficient piping systems cannot be overstated. Among the various components that ensure the integrity and functionality of these systems, stainless steel (SS) pipe couplings play a crucial role. These fittings serve the vital purpose of connecting two pieces of piping, enabling the seamless transfer of fluids and gases in diverse applications across industries.

What is an SS Pipe Coupling?

An SS pipe coupling is a device used to join two sections of pipe together. Made from high-quality stainless steel, these couplings are designed to withstand high pressure and temperature, making them suitable for a wide range of environments, from residential plumbing to industrial chemical processing. The durability of stainless steel also ensures resistance to corrosion, which is particularly beneficial in applications where exposure to moisture or corrosive substances is a concern.

Types of SS Pipe Couplings

There are several types of stainless steel pipe couplings available, each suited for specific applications and requirements. The most common include

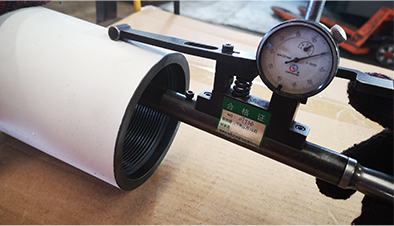

1. Threaded Couplings These are designed with internal threads that allow for easy connection to threaded pipe ends. This type is generally used in low-pressure systems and is favored for its simplicity and ease of installation.

2. Welded Couplings For high-pressure applications, welded couplings provide a strong and permanent connection. The process involves welding the coupling directly to the pipe, ensuring an impermeable seal that can withstand significant pressure.

ss pipe coupling

3. Socket Weld Couplings Similar to welded couplings, socket weld couplings are inserted into a recessed area of the pipe. This type is often used in systems requiring continuous flow without leaks, as it offers a robust connection.

4. Grooved Couplings These couplings use a rubber gasket and a clamp system to create a tight seal. They are particularly useful in applications that involve vibrations or movements, as the design allows for some flexibility.

Advantages of SS Pipe Couplings

The selection of stainless steel for pipe couplings offers numerous advantages. Firstly, stainless steel's inherent resistance to rust and corrosion ensures a long lifespan, reducing the need for frequent replacements and maintenance. Additionally, SS pipe couplings can withstand extreme temperatures, making them suitable for both hot and cold fluid transfer.

Moreover, the smooth internal finish of stainless steel minimizes friction, enhancing the flow rate of fluids. This efficiency is particularly important in larger systems where energy savings can lead to significant cost reductions. The versatility of SS couplings also allows their use in various applications, from domestic water supply systems to sophisticated HVAC and chemical processing operations.

Conclusion

In conclusion, SS pipe couplings are indispensable in modern piping systems. Their robust construction, resistance to corrosion, and versatility make them the preferred choice across multiple industries. As technology continues to advance, the design and functionality of these couplings will likely evolve, further enhancing their role in facilitating the efficient and safe transfer of fluids and gases. Investing in quality stainless steel pipe couplings is essential for ensuring the longevity and reliability of any piping installation.

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024