2 月 . 14, 2025 03:38

Back to list

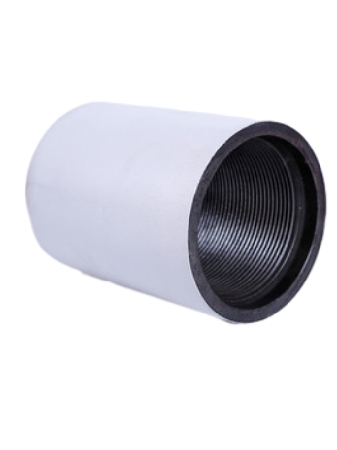

stainless steel coupling 1 2

In the world of fluid handling and piping systems, the importance of reliable connectors cannot be overstated, and stainless steel couplings, particularly in the 1/2-inch size, have proven themselves indispensable. These components are revered for their robustness, versatility, and ability to perform in a myriad of challenging environments. This guide highlights the critical aspects of stainless steel couplings - from their application to the features setting them apart, ensuring you make informed decisions for your projects.

Expertise in selecting the right coupling also involves understanding its role and function within the system design. The 1/2-inch size plays a crucial role in processes where space is a premium yet the demand for durability and reliability remains high. Installation experts appreciate these connectors not just for their mechanical benefits but also for the assurance of long-term cost savings and efficiency. Manufacturers of these stainless steel couplings take pride in adhering to stringent industry standards, which heightens the product's trustworthiness. Quality assurance through rigorous testing processes and compliance with international standards ensures that each coupling meets the necessary specifications for performance and safety. Hence, when sourcing these components, selecting those that meet recognized standards can significantly contribute to the overall success and reliability of the piping system. Given the evolving nature of plumbing and piping solutions, investments in technology and continuous improvement approaches have led to even more sophisticated designs in coupling technology. Advanced manufacturing processes such as precision casting and laser welding have further enhanced the properties and performance of stainless steel couplings, making them highly sought-after in high-tech and high-demand applications. In conclusion, the 1/2-inch stainless steel coupling is not merely a piece of hardware but a pivotal component that underpins the integrity and functionality of entire systems across various sectors. When prioritizing factors such as lifecycle costs, performance under duress, and industry compliance, these couplings emerge as a trusted solution. The expertise and commitment to quality that underpin the production of stainless steel couplings further elevate their status as the go-to choice for professionals seeking reliability, performance, and peace of mind in their mechanical and plumbing endeavors.

Expertise in selecting the right coupling also involves understanding its role and function within the system design. The 1/2-inch size plays a crucial role in processes where space is a premium yet the demand for durability and reliability remains high. Installation experts appreciate these connectors not just for their mechanical benefits but also for the assurance of long-term cost savings and efficiency. Manufacturers of these stainless steel couplings take pride in adhering to stringent industry standards, which heightens the product's trustworthiness. Quality assurance through rigorous testing processes and compliance with international standards ensures that each coupling meets the necessary specifications for performance and safety. Hence, when sourcing these components, selecting those that meet recognized standards can significantly contribute to the overall success and reliability of the piping system. Given the evolving nature of plumbing and piping solutions, investments in technology and continuous improvement approaches have led to even more sophisticated designs in coupling technology. Advanced manufacturing processes such as precision casting and laser welding have further enhanced the properties and performance of stainless steel couplings, making them highly sought-after in high-tech and high-demand applications. In conclusion, the 1/2-inch stainless steel coupling is not merely a piece of hardware but a pivotal component that underpins the integrity and functionality of entire systems across various sectors. When prioritizing factors such as lifecycle costs, performance under duress, and industry compliance, these couplings emerge as a trusted solution. The expertise and commitment to quality that underpin the production of stainless steel couplings further elevate their status as the go-to choice for professionals seeking reliability, performance, and peace of mind in their mechanical and plumbing endeavors.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products