2 月 . 19, 2025 09:20

Back to list

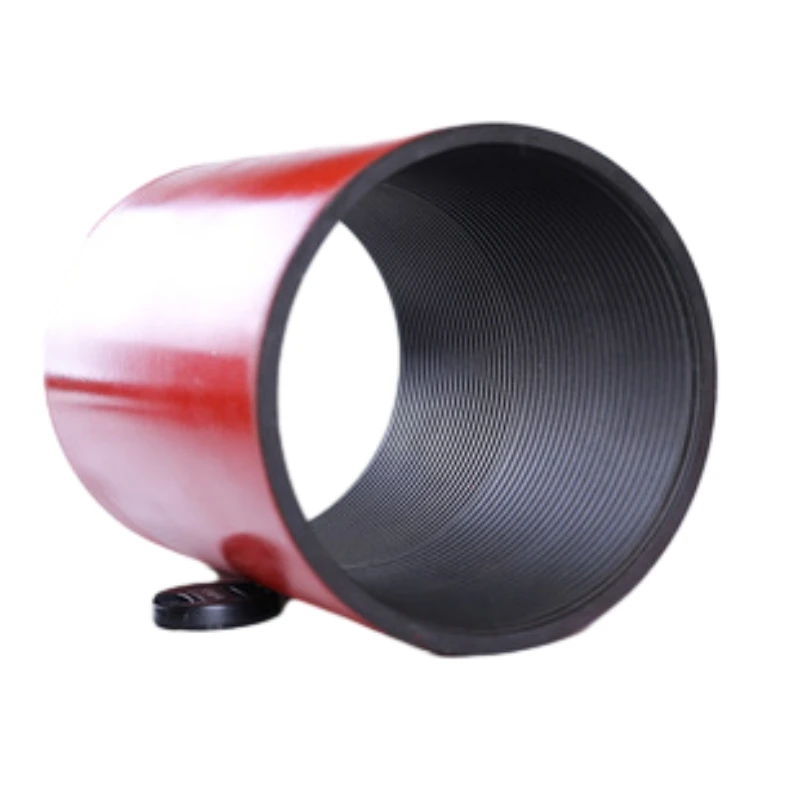

stainless steel reducer coupling

In industrial and commercial plumbing applications, the stainless steel reducer coupling often emerges as a pivotal component, offering unique advantages that cater to both performance and longevity. This essential tool plays a critical role in the seamless transition of pipe sizes, enabling efficient fluid handling in various systems.

Authoritative industry standards govern the production of stainless steel reducer couplings, ensuring they meet rigorous quality and safety benchmarks. Meeting these standards, such as those set by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO), is a testament to a manufacturer's commitment to excellence. These standards dictate the physical properties, dimensions, and material composition, providing peace of mind to engineers and end-users regarding the couplings’ durability and safety. The trustworthiness of stainless steel reducer couplings is further reinforced by their traceability. Reputable manufacturers offer comprehensive documentation, including material certificates and quality assurance reports, allowing for complete transparency regarding the origins and testing of each component. This traceability is crucial for industries where regulatory compliance and reliability are non-negotiable, such as pharmaceutical manufacturing and food processing. Moreover, the benefits of stainless steel reducer couplings extend beyond mere functionality. Their sleek and polished finish adds a level of sophistication to any industrial setup, while their recyclable nature aligns with growing sustainability goals. As industries worldwide strive to reduce their environmental footprint, choosing stainless steel components becomes a part of sustainable business practices, echoing corporate responsibility initiatives. For those in the market seeking reliable and efficient pipe fittings, stainless steel reducer couplings offer an unparalleled blend of resilience, reliability, and efficiency. Their unique advantages not only meet the practical demands of modern industry but also provide solutions that align with future-ready sustainability standards. Through meticulous engineering and adherence to stringent standards, these couplings remain a cornerstone of fluid handling technologies.

Authoritative industry standards govern the production of stainless steel reducer couplings, ensuring they meet rigorous quality and safety benchmarks. Meeting these standards, such as those set by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO), is a testament to a manufacturer's commitment to excellence. These standards dictate the physical properties, dimensions, and material composition, providing peace of mind to engineers and end-users regarding the couplings’ durability and safety. The trustworthiness of stainless steel reducer couplings is further reinforced by their traceability. Reputable manufacturers offer comprehensive documentation, including material certificates and quality assurance reports, allowing for complete transparency regarding the origins and testing of each component. This traceability is crucial for industries where regulatory compliance and reliability are non-negotiable, such as pharmaceutical manufacturing and food processing. Moreover, the benefits of stainless steel reducer couplings extend beyond mere functionality. Their sleek and polished finish adds a level of sophistication to any industrial setup, while their recyclable nature aligns with growing sustainability goals. As industries worldwide strive to reduce their environmental footprint, choosing stainless steel components becomes a part of sustainable business practices, echoing corporate responsibility initiatives. For those in the market seeking reliable and efficient pipe fittings, stainless steel reducer couplings offer an unparalleled blend of resilience, reliability, and efficiency. Their unique advantages not only meet the practical demands of modern industry but also provide solutions that align with future-ready sustainability standards. Through meticulous engineering and adherence to stringent standards, these couplings remain a cornerstone of fluid handling technologies.

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products