steel couplings for pipe

Steel Couplings for Pipe An Essential Component in Fluid Transport Systems

Steel couplings play a crucial role in the field of piping systems, particularly in the transport of fluids across various industries. These fittings are designed to connect two pieces of pipe together, ensuring a secure and leak-proof joint. The importance of selecting the right coupling cannot be overstated, as it impacts the overall integrity, efficiency, and safety of the piping system.

Steel Couplings for Pipe An Essential Component in Fluid Transport Systems

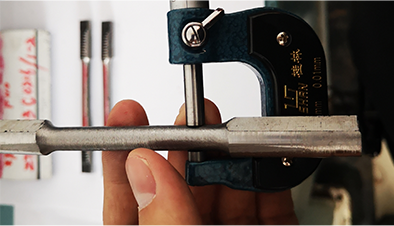

There are various types of steel couplings available, each designed for specific applications. For instance, threaded couplings allow for easy assembly and disassembly, providing flexibility in maintenance and repairs. On the other hand, welded couplings provide a more permanent joint, which is often necessary in environments where leaks could pose a significant risk. These couplings can also be used in conjunction with various pipe materials, including carbon steel, stainless steel, and alloy steel, further expanding their versatility.

steel couplings for pipe

When selecting a steel coupling, it is critical to consider several factors. The size and diameter of the pipes being connected, the type of fluid being transported, and the operating conditions, such as temperature and pressure, must all be taken into account. In addition, the compatibility of the coupling material with the fluid is essential to prevent corrosion and ensure the longevity of the joint. For example, the use of stainless steel couplings in corrosive environments can significantly extend the life of the piping system, reducing downtime and maintenance costs.

In recent years, advancements in manufacturing technologies have led to the development of specialized steel couplings that offer enhanced performance. Innovations such as coated couplings provide additional protection against corrosion, while flexible couplings accommodate slight misalignments between pipes, reducing stress on the joints. These advancements help industries improve the efficiency of their operations while maintaining safety standards.

Furthermore, adherence to industry standards and regulations is paramount when it comes to the installation and use of steel couplings. Compliance with organizations such as the American Society for Testing and Materials (ASTM) and the American National Standards Institute (ANSI) ensures that couplings meet specific quality and performance criteria. This compliance not only guarantees the reliability of the fittings themselves but also contributes to the overall safety of the fluid transport system.

In conclusion, steel couplings are an indispensable component in the design and maintenance of piping systems. Their strength, durability, and versatility make them suitable for a wide range of applications, while advancements in technology continue to enhance their performance. By understanding the various types of couplings available and their specific applications, industries can make informed decisions that optimize their fluid transport systems, ultimately leading to greater efficiency and safety in operations. Whether in construction, manufacturing, or any industry requiring fluid movement, the proper use of steel couplings is essential for success.

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024