1 月 . 17, 2025 04:38

Back to list

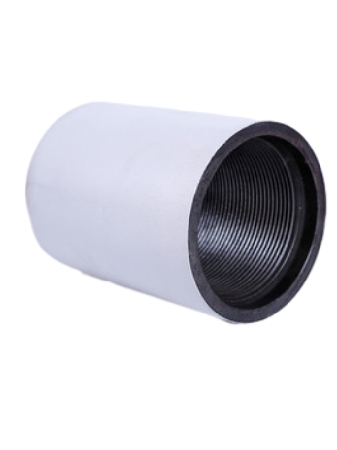

Crossover

Steel couplings for pipes are integral components in various industries, known for their robustness and versatility. Whether used in plumbing, oil refineries, or chemical processing plants, these couplings serve as the ultimate connectors, ensuring seamless transitions and secure joints. The importance of selecting the right steel coupling cannot be overstated, as it plays a crucial role in maintaining the integrity and efficiency of piping systems.

Trustworthiness of steel couplings aligns with the proven track record they boast in various applications. Users often seek testimonials and case studies that illustrate real-world scenarios where steel couplings have excelled. For instance, in the petrochemical industry, the reliability in handling volatile compounds under pressure has made steel couplings the component of choice. Engineers and technical specialists advocate for their use, drawing from comprehensive field data favorably comparing steel to other materials. Navigating the selection of appropriate steel couplings involves considering factors like pipe size, pressure ratings, and application-specific needs. For optimal performance, it's crucial to partner with suppliers who offer not just products but expert guidance on installation and maintenance. Understanding the nuances of different coupling types — from slip-on, threaded, to flanged variants — can profoundly influence the efficacy of the piping system. The innovation within steel couplings is rapidly evolving, with advancements such as improved sealing mechanisms and enhanced alloy compositions taking center stage. This progression furthers their application in increasingly specialized and challenging environments. In conclusion, the strategic implementation of steel couplings for pipes underscores their crucial role in robust, efficient, and reliable pipeline systems. The combination of steel's inherent properties with precise manufacturing ensures these components deliver consistent performance across various sectors. By focusing on experience, expertise, authoritativeness, and trustworthiness, companies can confidently rely on steel couplings to uphold the integrity of their piping infrastructures, thus ensuring operational excellence and safety.

Trustworthiness of steel couplings aligns with the proven track record they boast in various applications. Users often seek testimonials and case studies that illustrate real-world scenarios where steel couplings have excelled. For instance, in the petrochemical industry, the reliability in handling volatile compounds under pressure has made steel couplings the component of choice. Engineers and technical specialists advocate for their use, drawing from comprehensive field data favorably comparing steel to other materials. Navigating the selection of appropriate steel couplings involves considering factors like pipe size, pressure ratings, and application-specific needs. For optimal performance, it's crucial to partner with suppliers who offer not just products but expert guidance on installation and maintenance. Understanding the nuances of different coupling types — from slip-on, threaded, to flanged variants — can profoundly influence the efficacy of the piping system. The innovation within steel couplings is rapidly evolving, with advancements such as improved sealing mechanisms and enhanced alloy compositions taking center stage. This progression furthers their application in increasingly specialized and challenging environments. In conclusion, the strategic implementation of steel couplings for pipes underscores their crucial role in robust, efficient, and reliable pipeline systems. The combination of steel's inherent properties with precise manufacturing ensures these components deliver consistent performance across various sectors. By focusing on experience, expertise, authoritativeness, and trustworthiness, companies can confidently rely on steel couplings to uphold the integrity of their piping infrastructures, thus ensuring operational excellence and safety.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products