1 月 . 23, 2025 03:08

Back to list

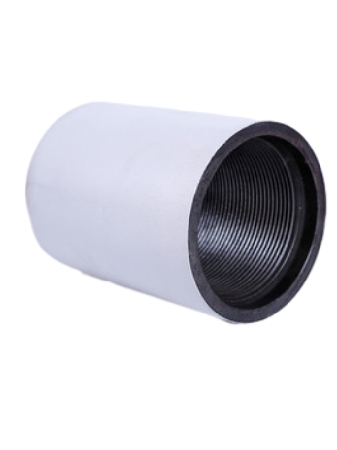

bull plug

Bull plugs, seemingly inconspicuous components in the oil and gas industry, are indispensable tools that ensure operational efficiency and safety. Understanding their role requires a thorough exploration of their functionality, materials, and the expertise they bring to drilling activities. The following narrative encapsulates seasoned insights, technical know-how, and established authority in their application, providing a unique perspective on their significance.

The authoritative role that bull plugs play is underscored by the meticulous standards and certifications they must meet. Organizations such as the American Petroleum Institute (API) and other national regulatory bodies set stringent guidelines to ensure these plugs can perform their function reliably across different scenarios. It is paramount for companies to choose bull plugs that comply with these regulations, ensuring that their operations meet both safety and regulatory standards. Trustworthiness in utilizing bull plugs stems from the constant innovations and improvements being made by leaders in the industry. Reputable manufacturers engage in rigorous testing regimes that simulate real-world conditions, allowing for the identification and resolution of any potential weaknesses before the product is even deployed. Such dedication not only elevates product reliability but also solidifies the trust customers place in these vital components. Further enhancing their credibility, field testimonials offer compelling evidence of their indispensability. Oil rig operators frequently report reduced downtime and maintenance costs thanks to the reliability and durability of high-quality bull plugs. These first-hand accounts are critical, as they provide empirical data supporting claims of efficiency, making the case for investing in superior products. In conclusion, bull plugs are far more than mere hardware additions to the oil and gas industry. Their role involves a blend of engineering prowess, strict adherence to safety and performance standards, and the informed choices made by experienced professionals. The successful deployment and operation of bull plugs stand as testaments to their crafted excellence and vital contribution to oil extraction technologies. As the backbone of any high-stakes drilling endeavor, choosing the right bull plug equates to safeguarding not only the equipment but also the overall success of the project. Such strategic decisions are where experience, expertise, authoritativeness, and trustworthiness converge, charting a course towards sustainable and efficient energy production.

The authoritative role that bull plugs play is underscored by the meticulous standards and certifications they must meet. Organizations such as the American Petroleum Institute (API) and other national regulatory bodies set stringent guidelines to ensure these plugs can perform their function reliably across different scenarios. It is paramount for companies to choose bull plugs that comply with these regulations, ensuring that their operations meet both safety and regulatory standards. Trustworthiness in utilizing bull plugs stems from the constant innovations and improvements being made by leaders in the industry. Reputable manufacturers engage in rigorous testing regimes that simulate real-world conditions, allowing for the identification and resolution of any potential weaknesses before the product is even deployed. Such dedication not only elevates product reliability but also solidifies the trust customers place in these vital components. Further enhancing their credibility, field testimonials offer compelling evidence of their indispensability. Oil rig operators frequently report reduced downtime and maintenance costs thanks to the reliability and durability of high-quality bull plugs. These first-hand accounts are critical, as they provide empirical data supporting claims of efficiency, making the case for investing in superior products. In conclusion, bull plugs are far more than mere hardware additions to the oil and gas industry. Their role involves a blend of engineering prowess, strict adherence to safety and performance standards, and the informed choices made by experienced professionals. The successful deployment and operation of bull plugs stand as testaments to their crafted excellence and vital contribution to oil extraction technologies. As the backbone of any high-stakes drilling endeavor, choosing the right bull plug equates to safeguarding not only the equipment but also the overall success of the project. Such strategic decisions are where experience, expertise, authoritativeness, and trustworthiness converge, charting a course towards sustainable and efficient energy production.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products