2 月 . 20, 2025 03:05

Back to list

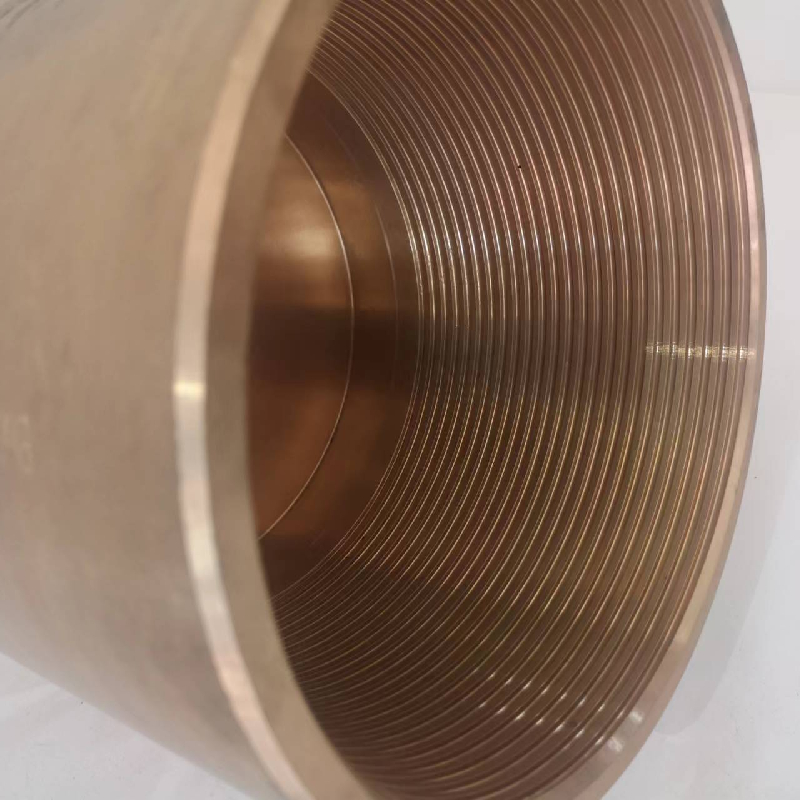

coupling stainless steel fitting

Choosing the right coupling stainless steel fitting can significantly impact the efficiency and longevity of industrial systems, making it an essential decision for those in the field. This article delves into the critical factors that ensure the selection of high-quality stainless steel fittings, relying on experienced insights and technical expertise that underline the importance of these components in various industrial applications.

Additionally, understanding the specific application of the coupling stainless steel fitting is so important. For example, industries requiring frequent inspection and maintenance will benefit from fittings that offer easy accessibility and disassembly. The design must support quick installation and removal while maintaining a secure and leak-proof connection during operation. This reduces downtime and improves operational efficiency, a benefit evident from both an operational and financial perspective. Keeping these factors in mind, selecting the right fitting also involves considering the total cost of ownership rather than simply the upfront purchase price. Cheap initial costs can often lead to higher expenses in the long term due to maintenance needs, potential failures, and replacements. Hence, investing in high-quality stainless steel fittings from trusted manufacturers can prevent costly operational hiccups and ensure continued efficiency and safety. Technical adherence isn't the only factor; expertise comes into play when considering the adaptability of fittings to future technological advancements. Modular designs in fittings facilitate upgrades and integration with newer systems without replacing the entire setup, a future-proofing strategy that seasoned industry professionals often advocate. Finally, creating a sustainable system also plays into the decision-making process, with stainless steel being an environmentally friendly choice due to its recyclability. Responsible sourcing and manufacturing processes are not only beneficial for the environment but can also enhance the corporate image and adhere to evolving international environmental standards. In conclusion, while selecting coupling stainless steel fittings, it is essential to leverage experience and expertise to make informed, strategic decisions. These decisions are crucial for effectively supporting current industrial processes and preparing for future advancements, establishing the foundation for a trustworthy and authoritative stance within the ever-evolving industrial landscape.

Additionally, understanding the specific application of the coupling stainless steel fitting is so important. For example, industries requiring frequent inspection and maintenance will benefit from fittings that offer easy accessibility and disassembly. The design must support quick installation and removal while maintaining a secure and leak-proof connection during operation. This reduces downtime and improves operational efficiency, a benefit evident from both an operational and financial perspective. Keeping these factors in mind, selecting the right fitting also involves considering the total cost of ownership rather than simply the upfront purchase price. Cheap initial costs can often lead to higher expenses in the long term due to maintenance needs, potential failures, and replacements. Hence, investing in high-quality stainless steel fittings from trusted manufacturers can prevent costly operational hiccups and ensure continued efficiency and safety. Technical adherence isn't the only factor; expertise comes into play when considering the adaptability of fittings to future technological advancements. Modular designs in fittings facilitate upgrades and integration with newer systems without replacing the entire setup, a future-proofing strategy that seasoned industry professionals often advocate. Finally, creating a sustainable system also plays into the decision-making process, with stainless steel being an environmentally friendly choice due to its recyclability. Responsible sourcing and manufacturing processes are not only beneficial for the environment but can also enhance the corporate image and adhere to evolving international environmental standards. In conclusion, while selecting coupling stainless steel fittings, it is essential to leverage experience and expertise to make informed, strategic decisions. These decisions are crucial for effectively supporting current industrial processes and preparing for future advancements, establishing the foundation for a trustworthy and authoritative stance within the ever-evolving industrial landscape.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products