1 月 . 23, 2025 02:22

Back to list

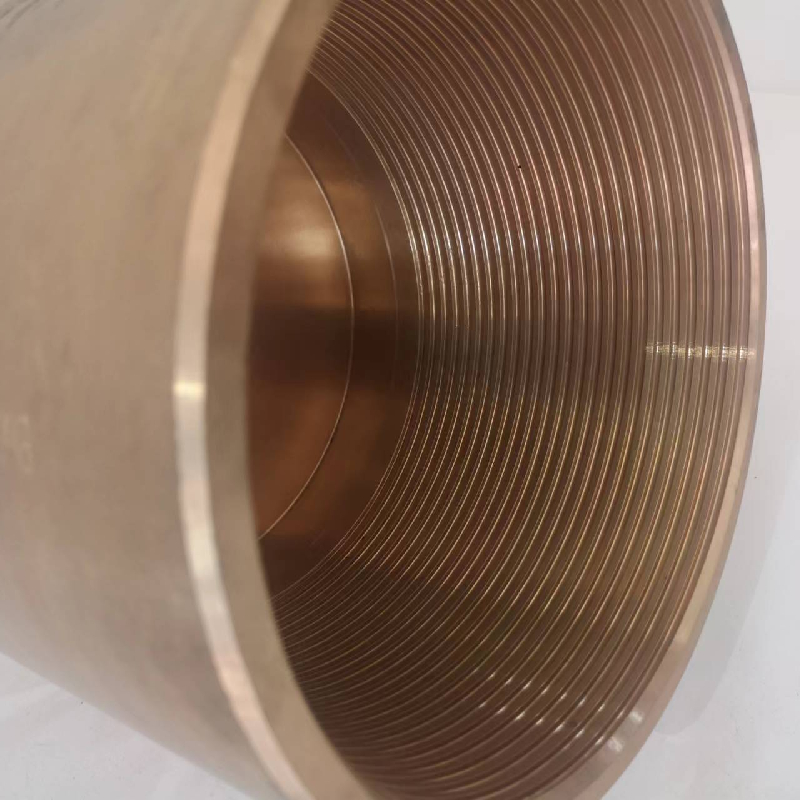

seating nipple tubing

Seating nipple tubing plays an integral role in the oil and gas industry by facilitating efficient well operations. Designed for reliability and durability, seating nipple tubing provides a secure section within the completion string where various downhole tools can be set or retrieved. This precision-engineered component exemplifies an essential product for ensuring fluid control and optimizing production output.

The authoritative nature of seating nipple tubing stems from its wide acceptance and standardized design within the industry. Organizations like the American Petroleum Institute (API) provide comprehensive standards that govern its manufacture and installation. Compliance with these standards assures businesses of the component's quality and compatibility across diverse well designs and configurations. The adherence to these guidelines further underscores its reliability as a trusted component in well operations. Trustworthiness is established over time through proven performance and reliability in the field. Companies that consistently invest in rigorous testing and quality assurance processes gain a competitive edge. They ensure their seating nipple tubing products not only meet but exceed the prescribed industry standards. Furthermore, a focus on innovation in design and materials can contribute to advancements that enhance performance under extreme conditions, building further trust with end users. In conclusion, seating nipple tubing is a critical product for enhancing operational efficiency in oil and gas exploration and production. It ingeniously balances mechanical precision with material strength to provide a reliable point for setting downhole equipment, thus ensuring fluid control and facilitating optimal production. By focusing on expertise in installation, compliance with authoritative standards, and establishing a track record of trust and reliability, seating nipple tubing remains an indispensable asset in modern well operations.

The authoritative nature of seating nipple tubing stems from its wide acceptance and standardized design within the industry. Organizations like the American Petroleum Institute (API) provide comprehensive standards that govern its manufacture and installation. Compliance with these standards assures businesses of the component's quality and compatibility across diverse well designs and configurations. The adherence to these guidelines further underscores its reliability as a trusted component in well operations. Trustworthiness is established over time through proven performance and reliability in the field. Companies that consistently invest in rigorous testing and quality assurance processes gain a competitive edge. They ensure their seating nipple tubing products not only meet but exceed the prescribed industry standards. Furthermore, a focus on innovation in design and materials can contribute to advancements that enhance performance under extreme conditions, building further trust with end users. In conclusion, seating nipple tubing is a critical product for enhancing operational efficiency in oil and gas exploration and production. It ingeniously balances mechanical precision with material strength to provide a reliable point for setting downhole equipment, thus ensuring fluid control and facilitating optimal production. By focusing on expertise in installation, compliance with authoritative standards, and establishing a track record of trust and reliability, seating nipple tubing remains an indispensable asset in modern well operations.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products