2 月 . 02, 2025 01:35

Back to list

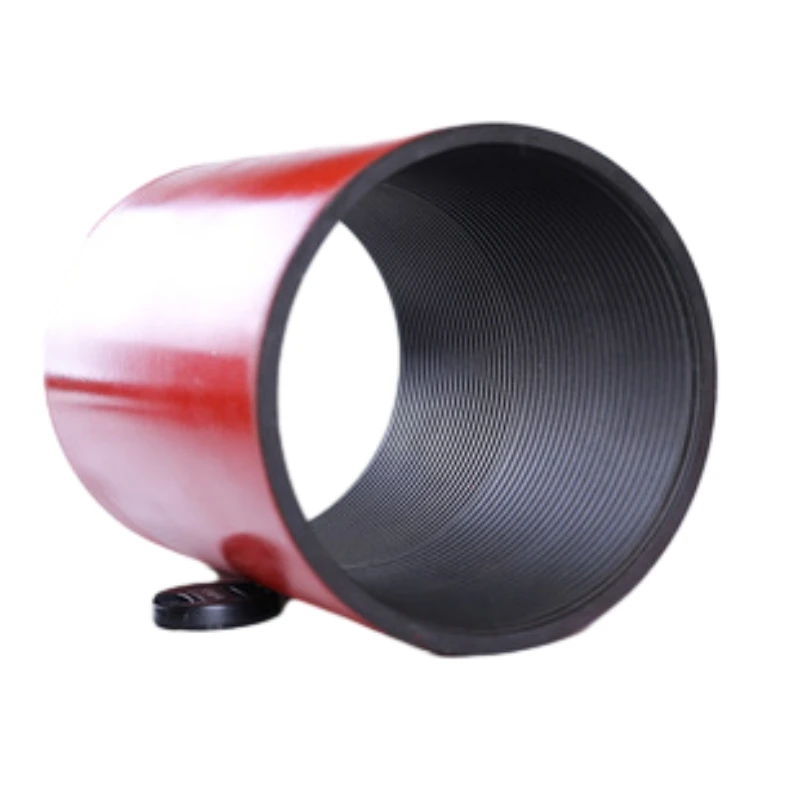

threaded bull plug

Threaded bull plugs are vital components in the oil and gas industry, particularly in the context of pressure control and safety systems. The significance of these devices extends beyond their apparent simplicity, serving both as a mechanical stopper and a key to maintaining the integrity of piping systems, which they cap securely. Whether you are an engineer on site or part of a purchasing team sourcing vital components, understanding the nuanced capabilities and applications of threaded bull plugs can significantly impact operational efficiency and safety.

When evaluating the expertise required to choose the right threaded bull plug for a specific application, one must consider parameters such as thread type, pressure rating, and material compatibility. Compatibility is particularly essential in preventing corrosion or chemical reactions that could weaken the component over time. Professionals selecting these plugs often weigh their decisions heavily on accurate data and supplier reputations to secure components that align with their systems' operational needs. From a practical, experience-based standpoint, the installation process of threaded bull plugs is straightforward, yet it demands a methodical approach. Proper alignment and thread matching are critical to producing an effective seal. Misalignment can lead to cross-threading, which compromises both the plug and the pipeline’s integrity. Technicians often rely on best practice methodologies informed by years of industry experience to perform installations that are both efficient and flawless. The global market today demands not just components that work, but components supported by a supplier's demonstrated authority and reliability. Therefore, when acquiring threaded bull plugs, collaboration with manufacturers who maintain high standards of production and quality control is crucial. These manufacturers often provide detailed product documentation and support, reinforcing their authenticity and commitment to delivering components that meet or exceed industry norms. In conclusion, threaded bull plugs are more than mere mechanical fittings. They are an intersection of engineering design, material science, and operational expertise, delivering results that speak to safety and efficiency. Their true value is realized in applications that stake their success on reliable, predictable performance, making them indispensable components in many industrial sectors. As safety regulations and operational demands evolve, the expertise behind these seemingly simple devices will continue to form the backbone of successful industrial applications worldwide.

When evaluating the expertise required to choose the right threaded bull plug for a specific application, one must consider parameters such as thread type, pressure rating, and material compatibility. Compatibility is particularly essential in preventing corrosion or chemical reactions that could weaken the component over time. Professionals selecting these plugs often weigh their decisions heavily on accurate data and supplier reputations to secure components that align with their systems' operational needs. From a practical, experience-based standpoint, the installation process of threaded bull plugs is straightforward, yet it demands a methodical approach. Proper alignment and thread matching are critical to producing an effective seal. Misalignment can lead to cross-threading, which compromises both the plug and the pipeline’s integrity. Technicians often rely on best practice methodologies informed by years of industry experience to perform installations that are both efficient and flawless. The global market today demands not just components that work, but components supported by a supplier's demonstrated authority and reliability. Therefore, when acquiring threaded bull plugs, collaboration with manufacturers who maintain high standards of production and quality control is crucial. These manufacturers often provide detailed product documentation and support, reinforcing their authenticity and commitment to delivering components that meet or exceed industry norms. In conclusion, threaded bull plugs are more than mere mechanical fittings. They are an intersection of engineering design, material science, and operational expertise, delivering results that speak to safety and efficiency. Their true value is realized in applications that stake their success on reliable, predictable performance, making them indispensable components in many industrial sectors. As safety regulations and operational demands evolve, the expertise behind these seemingly simple devices will continue to form the backbone of successful industrial applications worldwide.

Next:

Latest news

-

Unlock the Benefits of Pup Joints for Your OperationsNewsOct.31,2024

-

The Quality of Casing Couplings from ChinaNewsOct.31,2024

-

The Essential Role of Pup Joints in Drilling OperationsNewsOct.31,2024

-

The Benefits of Tubing Couplings for Your ProjectsNewsOct.31,2024

-

Enhance Your Drilling Operations with Tubing Pup JointsNewsOct.31,2024

-

Elevate Your Drilling Operations with Tubing CrossoversNewsOct.31,2024

Related Products